- Joined

- Dec 18, 2019

- Messages

- 6,447

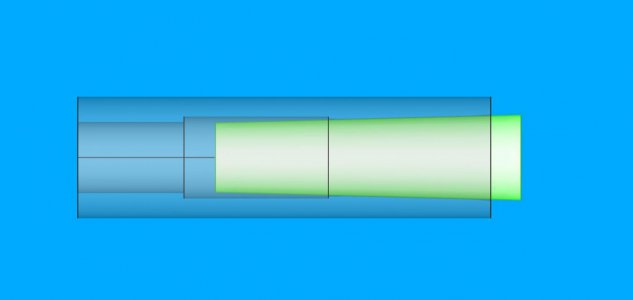

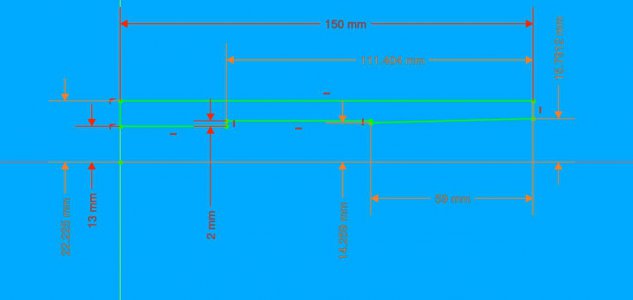

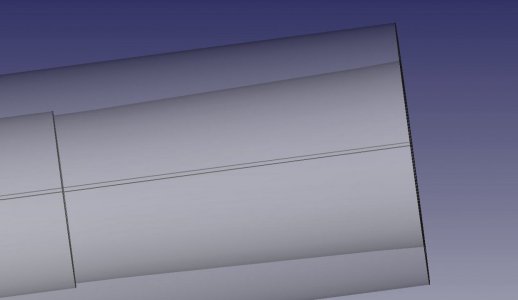

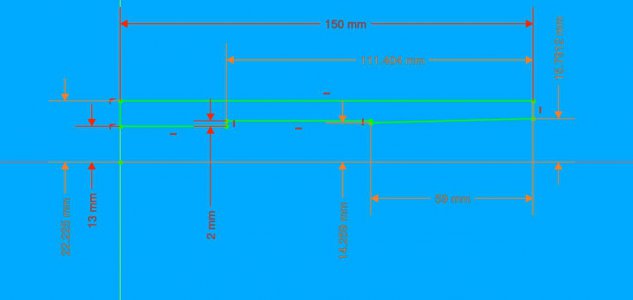

To solve the problem of my tapers not fitting, I made a model of the MT4 taper and the spindle socket of my G0772Z (G0602). I made the two bodies coaxial and slid one body into the other. (Done via changing the X axis attachment point of the sketch.) I made the socket transparent, and the taper opaque. Even when the mt4 tool is made invisible, the spindle taper seems to have flared out ends at the start and end of the taper. The sketch itself does not have this.

I have set the Anti-Aliasing to MSAA 8x, naively thinking this might be better, but the false flair seems to still be there. Have tried line smoothing, MSAA 2x as well and looks the same. Using orthographic rendering.

Anyone have an idea what is causing this?

I have set the Anti-Aliasing to MSAA 8x, naively thinking this might be better, but the false flair seems to still be there. Have tried line smoothing, MSAA 2x as well and looks the same. Using orthographic rendering.

Anyone have an idea what is causing this?