These FIRST kids are amazing. A number of years ago, a friend of my wife was the regional director of the program and we went to several of the competitions, including the regional finals. After I retired, I entertained the idea of acting as a mentor. I went to one of their weekly work sessions and concluded that there wasn't much that I could add. I asked the director what I would be expected to do as a mentor and was told, mainly set on the sideline and offer morale support.

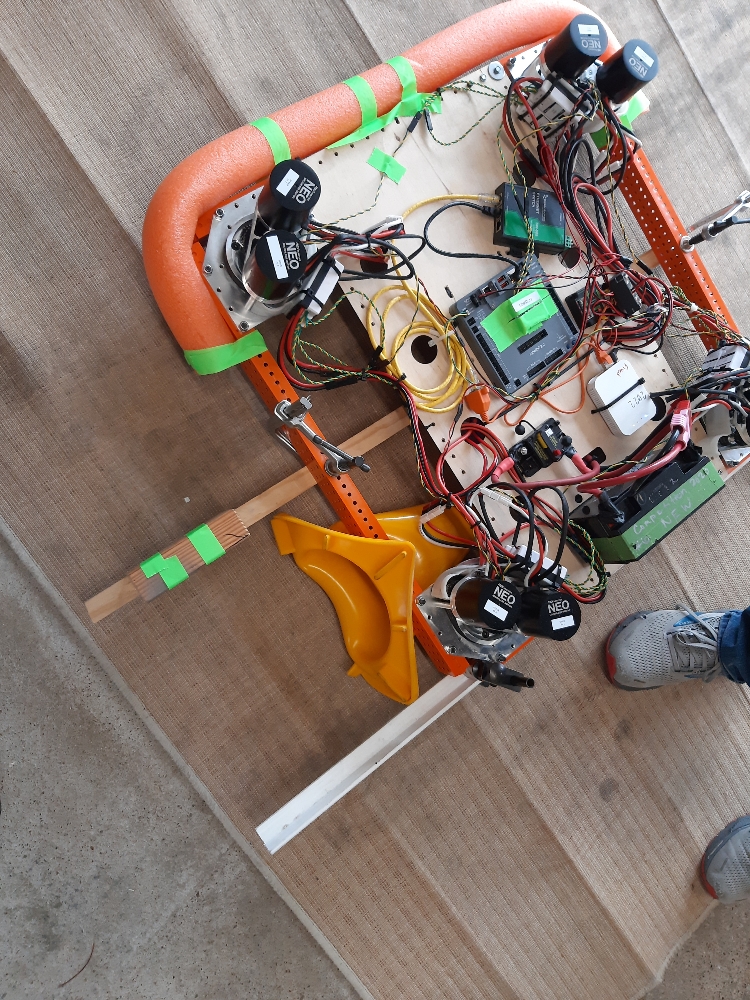

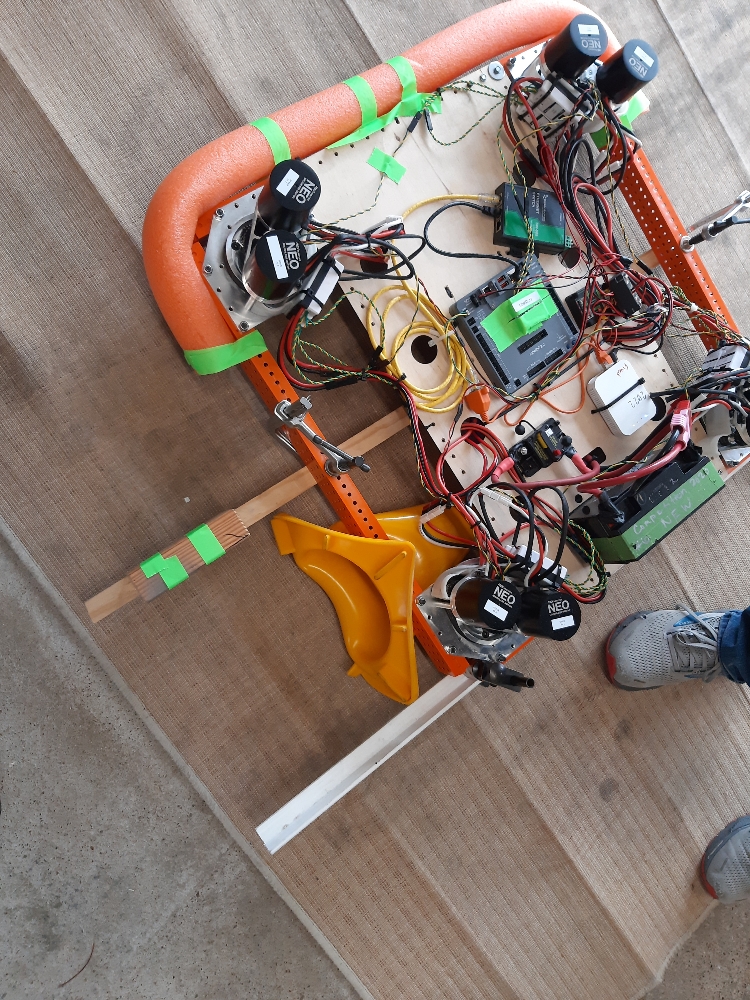

After observing the group, the Badger Bots, in action, it was apparent that they were quite capable of dealing with all aspects of the project, from project management and budget control to manual and CNC machining to writing software. Having spent the last sixteen years of my professional life in product development in the biotech and medical device sectors, what these kids accomplished in six weeks would normally take a professional team a year or more.