- Joined

- May 14, 2014

- Messages

- 3

Just having a little fun pushing my knowledge base further into the 3-D machining realm...

My thanks to my bosses for allowing and encouraging some creative endeavors...

So a friend of mine asked me to make her a replacement for a 2" ball she was using for a rear steer control knob... (hydraulic control for rear steer 2.5 ton Rockwell axle)

This is her rig... It's Nightmare Before Christmas themed... Stainless tube, big block engine, 46" tires, lots of goodies...

This is her dash... Notice the ball wrapped in athletic tape... This is how she controls the steering of the rear axle...

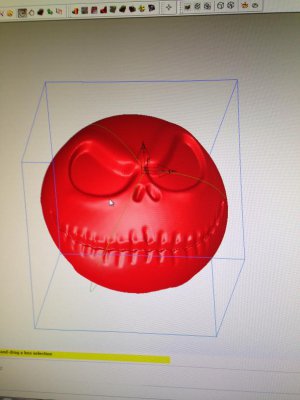

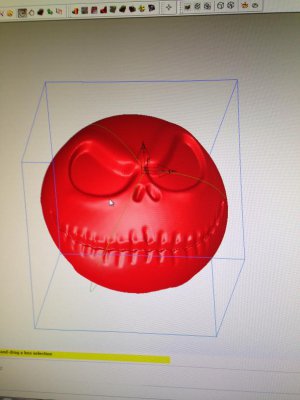

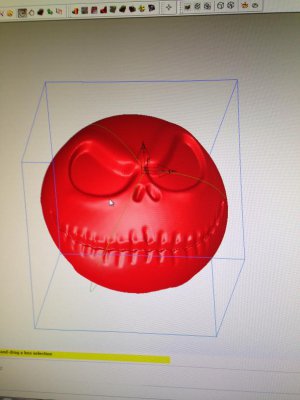

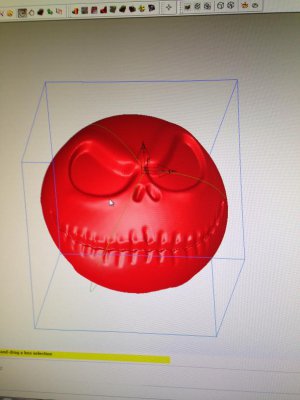

In addition to machinist, I'm also a computer geek, so this was what I created...

Tested it out on a scrap block of aluminum... (4 hour run time)

Bought 2" sphere of polished 304 stainless, drilled and tapped M8x1.25 into the sphere...

Made a fixture matching the curvature of the sphere, made more than enough clearance, and put in a through hole to use a screw to properly secure work piece from underneath...

Jack roughed out...

First finish pass (24 hours of 1/8 ball mill work in the stainless!)

A few more hours with a 1/16 ball mill for some additional details in the eyes and mouth...

Voila, finished... 30 hour run time in stainless... but he looks GOOD...

Installed in her rig (~1000 miles from me)... Turned out well, but I think I'll make another out of aluminum... this one is 17 ounces!

Thanks for reading/viewing... Have a good one!

My thanks to my bosses for allowing and encouraging some creative endeavors...

So a friend of mine asked me to make her a replacement for a 2" ball she was using for a rear steer control knob... (hydraulic control for rear steer 2.5 ton Rockwell axle)

This is her rig... It's Nightmare Before Christmas themed... Stainless tube, big block engine, 46" tires, lots of goodies...

This is her dash... Notice the ball wrapped in athletic tape... This is how she controls the steering of the rear axle...

In addition to machinist, I'm also a computer geek, so this was what I created...

Tested it out on a scrap block of aluminum... (4 hour run time)

Bought 2" sphere of polished 304 stainless, drilled and tapped M8x1.25 into the sphere...

Made a fixture matching the curvature of the sphere, made more than enough clearance, and put in a through hole to use a screw to properly secure work piece from underneath...

Jack roughed out...

First finish pass (24 hours of 1/8 ball mill work in the stainless!)

A few more hours with a 1/16 ball mill for some additional details in the eyes and mouth...

Voila, finished... 30 hour run time in stainless... but he looks GOOD...

Installed in her rig (~1000 miles from me)... Turned out well, but I think I'll make another out of aluminum... this one is 17 ounces!

Thanks for reading/viewing... Have a good one!