Hey guys,

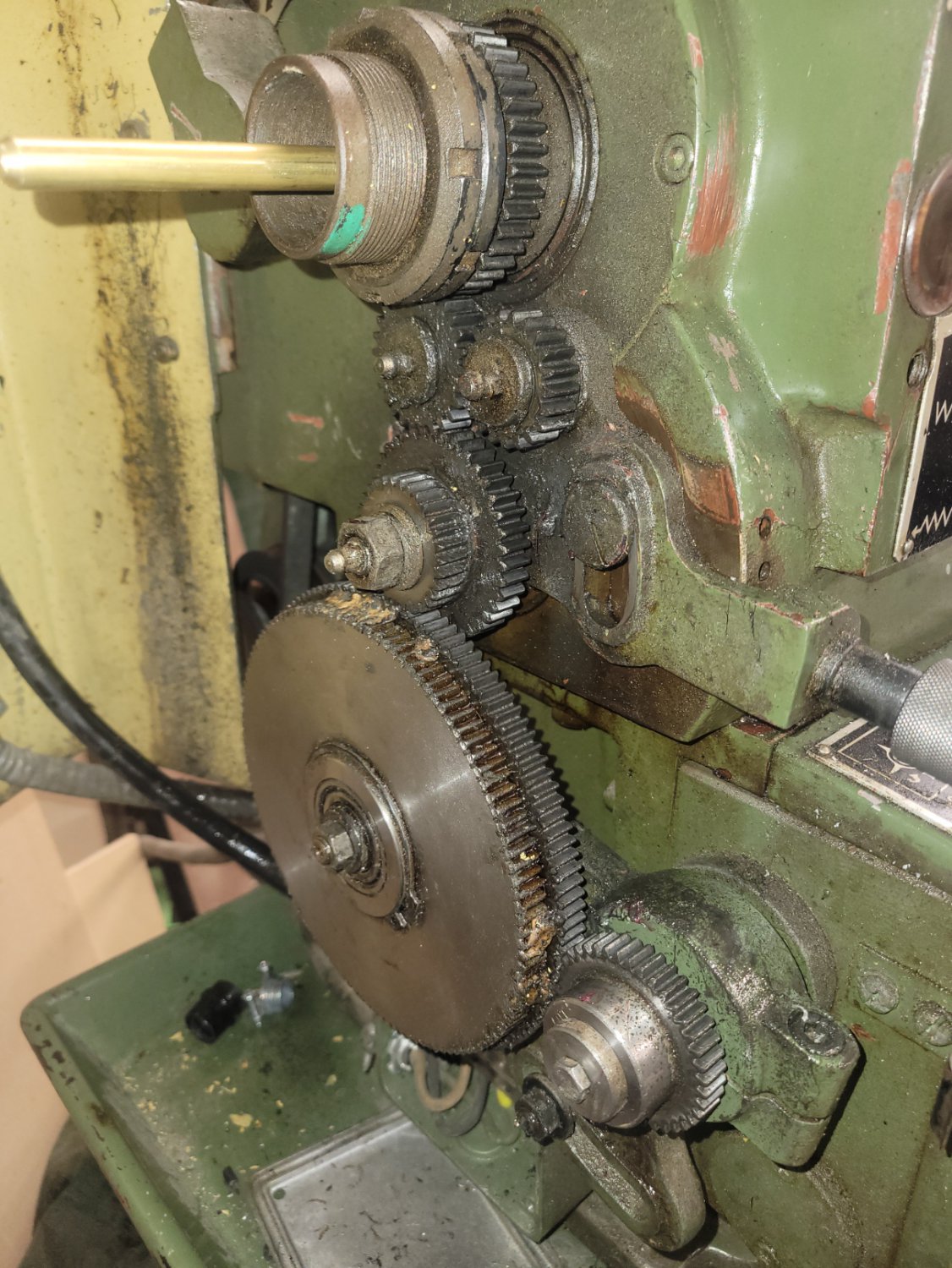

Recently acquired my first lathe a 83 Jet 1236py. I've read every thread on here about them to get some good general knowledge. I got some basic tooling and have done some facing, turning, parting, boring, drilling etc in some 6061 and brass. I recently decided to try some practice single point threading and ran into what I think may be an issue but I don't know. I can't get the machine to thread a pitch correctly during my scratch pass. I've tried large and small pitches (all SAE no metric) and they are consistent but don't match up with the thread gauge at all. That led me to make sure my gears where set up correctly and deciphering the metal tags and charts on the machine. The way I see it (for SAE its supposed to go through 40T 127T and 40T. The top gear above the 127T and below the reversing gears is the 40 and 34T the 40T is receiving the force from above and the 34 is transferring it to the 127T. Is this correct? In looking at any and all pictures online it appears to be set up correct currently. If I turn swap around the 34 and the 40 it doesn't touch and mesh the reversing gears.

Am I missing a second 40T gear that goes in place of the smaller 34T that is riding on the 127? Or in my ignorance do I have something else not set up correct? More pictures can be provided if necessary.

Recently acquired my first lathe a 83 Jet 1236py. I've read every thread on here about them to get some good general knowledge. I got some basic tooling and have done some facing, turning, parting, boring, drilling etc in some 6061 and brass. I recently decided to try some practice single point threading and ran into what I think may be an issue but I don't know. I can't get the machine to thread a pitch correctly during my scratch pass. I've tried large and small pitches (all SAE no metric) and they are consistent but don't match up with the thread gauge at all. That led me to make sure my gears where set up correctly and deciphering the metal tags and charts on the machine. The way I see it (for SAE its supposed to go through 40T 127T and 40T. The top gear above the 127T and below the reversing gears is the 40 and 34T the 40T is receiving the force from above and the 34 is transferring it to the 127T. Is this correct? In looking at any and all pictures online it appears to be set up correct currently. If I turn swap around the 34 and the 40 it doesn't touch and mesh the reversing gears.

Am I missing a second 40T gear that goes in place of the smaller 34T that is riding on the 127? Or in my ignorance do I have something else not set up correct? More pictures can be provided if necessary.