- Joined

- Oct 17, 2012

- Messages

- 126

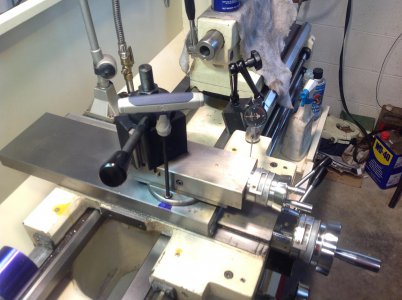

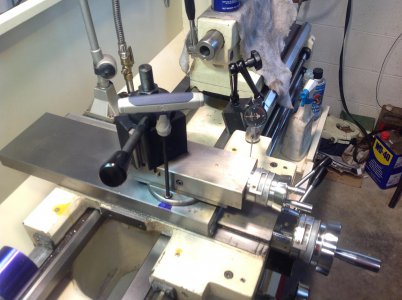

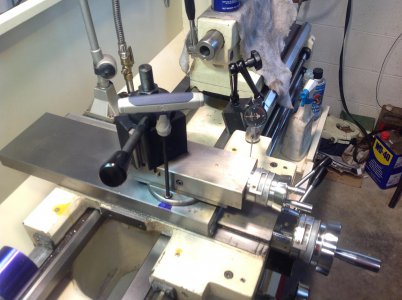

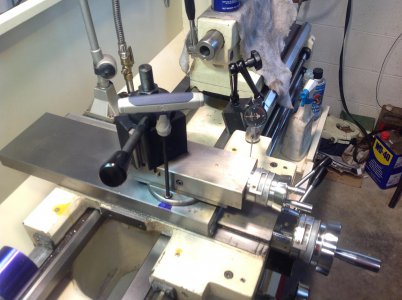

As you know the protractor on the cross slide is difficult to use and crudely stamped. Not only that it does not have cardinal points and lacks a vernier. Maybe this will help.

1. Locate roughly the rotational centerline of the compound and estimate 90^. Set the DI on zero at that point. Then traverse the cross slide, say 3" or 6" on the DRO. Slowly adjusting 'til you get to zero all the way. Any mis-estimate of the compound rotation center will be corrected by trial and error. Mark a cardinal point for 90^.

OK how much is good 'nuff. Well say you got 0.0015 in 3. Well the sin = tan for small angles. So .0015/3 = 0.0005. And the Arctan of .0005 is 0.0286 deg which = 0^01'45". We can get about 20" accuracy. So I quit at 0.0005" in 3". 0.0005/3 = 0.00016

Arctan 0.00016 = 0^00'34". We can get a little better if desired. BUT

2. Then we have a good reference. So insert a protractor in the tailstock and set zero. Then align the tool post to the protractor which is set at 90^ and tighten tool post. Now the tool post is aligned with the cross slide/compound slide. The one you see here came from Bridge City Tool Works (about 15 yrs ago)

3. Back the saddle away and set the desired angle. More to come. Lunch time.

1. Locate roughly the rotational centerline of the compound and estimate 90^. Set the DI on zero at that point. Then traverse the cross slide, say 3" or 6" on the DRO. Slowly adjusting 'til you get to zero all the way. Any mis-estimate of the compound rotation center will be corrected by trial and error. Mark a cardinal point for 90^.

OK how much is good 'nuff. Well say you got 0.0015 in 3. Well the sin = tan for small angles. So .0015/3 = 0.0005. And the Arctan of .0005 is 0.0286 deg which = 0^01'45". We can get about 20" accuracy. So I quit at 0.0005" in 3". 0.0005/3 = 0.00016

Arctan 0.00016 = 0^00'34". We can get a little better if desired. BUT

2. Then we have a good reference. So insert a protractor in the tailstock and set zero. Then align the tool post to the protractor which is set at 90^ and tighten tool post. Now the tool post is aligned with the cross slide/compound slide. The one you see here came from Bridge City Tool Works (about 15 yrs ago)

3. Back the saddle away and set the desired angle. More to come. Lunch time.

Last edited: