Hello all,

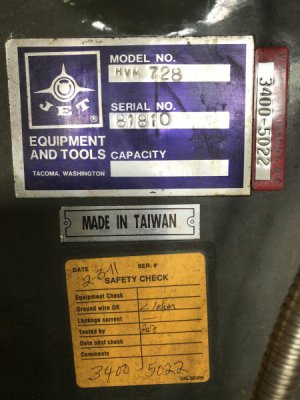

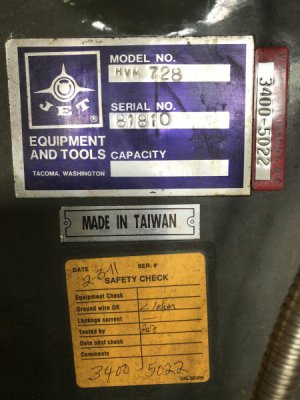

I'm new to machining (and learning a lot from this forum) and I recently purchased a Jet HVM-728 that was removed from service in a nearby VA Hospital welding shop. The machine looks to be in good shape but it appears as if it has never been cleaned in 30+ years! One big issue that I have to address is that when they took it out of service, they cut a great deal of wiring in the electrical panel. I have seen this happen on several pieces of electrical equipment removed from the VA, and it makes no sense to me why they do this. I’m certain they cut wires and removed a 14 position terminal block. I was just checking to see if there is anyone on the forum who has a similar machine and can help me out with this issue by taking some pictures of the inside of the electrical panel of their HVM-728. This might help in determining a sensible routing to this wiring mess I have acquired. Thanks for any help you can give me on this. (I'm not certain if the pics will post correctly, as I have little experience on posting pics!)

I'm new to machining (and learning a lot from this forum) and I recently purchased a Jet HVM-728 that was removed from service in a nearby VA Hospital welding shop. The machine looks to be in good shape but it appears as if it has never been cleaned in 30+ years! One big issue that I have to address is that when they took it out of service, they cut a great deal of wiring in the electrical panel. I have seen this happen on several pieces of electrical equipment removed from the VA, and it makes no sense to me why they do this. I’m certain they cut wires and removed a 14 position terminal block. I was just checking to see if there is anyone on the forum who has a similar machine and can help me out with this issue by taking some pictures of the inside of the electrical panel of their HVM-728. This might help in determining a sensible routing to this wiring mess I have acquired. Thanks for any help you can give me on this. (I'm not certain if the pics will post correctly, as I have little experience on posting pics!)