I am trying to install a JET 350196 Z-Axis Knee Powerfeed on a JET JTM-4VS-1 Vertical Mill.

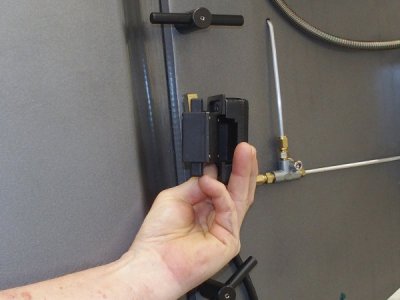

The Powerfeed came with a bracket kit for the Limit Switch assembly that seems inadequate. However, it wouldn't be the first time I've looked at something and missed the obvious. I was wondering if anyone had a JET Knee Mill with a Z-Axis Knee Powerfeed. If so, pictures of the Limit Switch Assembly would be appreciated.

Scott

The Powerfeed came with a bracket kit for the Limit Switch assembly that seems inadequate. However, it wouldn't be the first time I've looked at something and missed the obvious. I was wondering if anyone had a JET Knee Mill with a Z-Axis Knee Powerfeed. If so, pictures of the Limit Switch Assembly would be appreciated.

Scott