- Joined

- Mar 20, 2014

- Messages

- 440

After many months of resherching milling machines, and, for that matter, if I even had use for a mill, I finally decided, after my Augest to November bout with the big C, that indeed, I had worked hard all my life, and should get what I wanted. I picked the PM 727M as the perfect size for my limited garage space, and was ready to order. Well, my wife and 2 sons, having watched me go through the cancer treatments, secretely overruled my decision, and called Matt to order a PM 932M-PDF. That story is here: http://www.hobby-machinist.com/threads/got-a-new-pm-mill-comming.39934/ -------- And so, my journey began.

At 6' 3" tall, I new that I needed a "riser base", to bring the mill up to me, rather than bending over to it, and living in earthquake country, I also wanted the top heavy mill to have much more stability, than what the 19" wide PM base provided. So about 2 weeks before the delivery date, I started working on my base. From some forum info I read, I decided I wanted an extra 12" of height over the stock set up, and for stability I went with 40" outriggers. Between some 8" I-beams I had, and the adjustable feet I would make, (like what I made for my lathe), that would get me the 12" lift I wanted. These pics are the start of the feet and base:

There is one thing to note, the finished base above has a set of casters on it. At this point it had my adjustable feet welded on but it wasn't painted yet, so no pic. As for the casters, well read on .

Unfortunately, I wasn't aware of a plan being talked about, by 6 incredably generous forum members, who contacted my son about building me a base to surprise me. You can learn about that here: http://www.hobby-machinist.com/threads/a-thank-you-to-6-very-generous-members-a-must-read.40706/ By the time the mill arrived, the day before Turkey Day, my base only needed the mounting holes drilled and paint, and yet, between the holidays, and more "old man issues" coming up, it took the next 2 months before I finally plugged it in! Now, this wouldn't be a "new machine thread" if it didn't include a few of the standard arrival and set up pics:

Shortly after Thanksgiving, once some "generous forum members", AirWolf-- Wrmiller--Coolidge--FrankO--Zmotorsports and Matt from Quality Machine Tools, found out that I had already made the base, I got a message from Coolidge. He said that he already had the casters, for the base build, they were planning and if I could use them, he would send them to me. At first I told him to keep them for one of his future projects, but he insisted, and wouldn't even let me pay for shipping !! How's that for "Christmas generosity". So, after very carefully cutting the adjusting bosses, for my feet, off the ends of the base I installed these Footmaster casters. And, am I glad I did, these things are great. At first I thought there wouldn't be enough adjustment to get the mill level on my uneven garage floor, but, there was plenty, and no tools needed. They have a ratcheting lever that pulls out for adjusting and , as far as easy, well, my son was visiting this past weekend (lives 3 hrs. away) and hadn't seen the casters yet. He made his wife come out to see how easily they adjust and, well, the next morning I was out re-leveling the mill. One final THANK YOU to Coolidge and the kind forum members, and I'll move on.

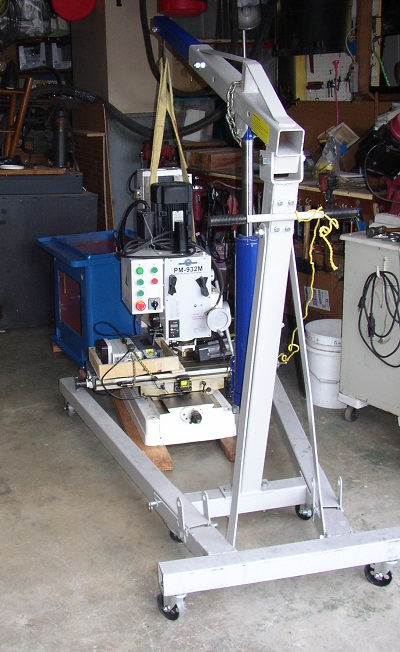

Now, one last step, and my mill would be ready. Obviously, I wasn't going to be able to use the shop crane, as the base was much to wide to fit between its legs. These next pics show how I got it up 14" off the floor in order to roll the base under, and bolt them up. One note here, I'll be the first to admit, these pics look a little scary, safety wise, but, I assure you, all was very solid. Each lift with the bottle jack was only 1 1/2" (thickness of a 2X4) at a time, and all cribbing was secured to the one below it with deck screws. In fact, I felt confident enough about it that I left it up on the cribbing for 2 days. OK, I'll be honest. It wasn't by choice, after spending an afternoon crawling on the concrete floor, to get it up there, it took 2 days for this old man's bones to recuperate.

Then, it was just a matter of placing it, with it's back against the back of my Logan 2557 lathe. They both share a set of 2X4 studs that come down from rafters to floor with all my electrical outlets, as well as the VFD on the lathe side, and soon a clamp set on the mill side. I made the 2X4 "wall" frame 24" apart to mount a metal cabinet for lathe tooling, but since getting the mill, decided that the light from the window was more beneficial, so took the cabinet down, and will put shelves between the studs. Last pic Is where it will stay and get used. Oh, and I will probably paint the bare wood and red cabinets you see in some of the pics (pretty mill needs pretty surroundings?) but then again, last pic was taken 2 weeks ago, and today, its all oily, with chips everywhere. So painting isn't a priority (function over form).

Sorry this has been so long, but I need to share some thoughts. First off, I must brag. I took a chance making the base a full 12" high, but it is perfect for me, and as for stability, well, if during an earthquake, it falls over, I guarante you, it will be from the house falling on top of it. The mill seems perfect to me, but remember I've never run a mill, ever. I've been mostly practicing with facing, cutting a slot or two, and drilling holes in scrap. I used it enough to break it in well, and changed the gear head oil, with quality oil. Haven't seen any leeks, and the table and head move very smooth. Not sure what else I should be saying about it, other than I love it! Have been spending most of my time with it. Believe it or not, I needed a 5/8" set screw for something, and rather than drive 2 miles and pay maybe ? a buck fifty ? , I spent a fun afternoon, making one out of a cut off bolt, and roughed out the hex hole for the allen wrench in the top. Silly, yes, but lots of fun . I'm sure there are other things that I should be commenting on, so please reply, with any questions. I am coming up with some newbe questions, but will ask them in other threads. Thanks for taking the time to share my excitement, JR49

At 6' 3" tall, I new that I needed a "riser base", to bring the mill up to me, rather than bending over to it, and living in earthquake country, I also wanted the top heavy mill to have much more stability, than what the 19" wide PM base provided. So about 2 weeks before the delivery date, I started working on my base. From some forum info I read, I decided I wanted an extra 12" of height over the stock set up, and for stability I went with 40" outriggers. Between some 8" I-beams I had, and the adjustable feet I would make, (like what I made for my lathe), that would get me the 12" lift I wanted. These pics are the start of the feet and base:

There is one thing to note, the finished base above has a set of casters on it. At this point it had my adjustable feet welded on but it wasn't painted yet, so no pic. As for the casters, well read on .

Unfortunately, I wasn't aware of a plan being talked about, by 6 incredably generous forum members, who contacted my son about building me a base to surprise me. You can learn about that here: http://www.hobby-machinist.com/threads/a-thank-you-to-6-very-generous-members-a-must-read.40706/ By the time the mill arrived, the day before Turkey Day, my base only needed the mounting holes drilled and paint, and yet, between the holidays, and more "old man issues" coming up, it took the next 2 months before I finally plugged it in! Now, this wouldn't be a "new machine thread" if it didn't include a few of the standard arrival and set up pics:

Shortly after Thanksgiving, once some "generous forum members", AirWolf-- Wrmiller--Coolidge--FrankO--Zmotorsports and Matt from Quality Machine Tools, found out that I had already made the base, I got a message from Coolidge. He said that he already had the casters, for the base build, they were planning and if I could use them, he would send them to me. At first I told him to keep them for one of his future projects, but he insisted, and wouldn't even let me pay for shipping !! How's that for "Christmas generosity". So, after very carefully cutting the adjusting bosses, for my feet, off the ends of the base I installed these Footmaster casters. And, am I glad I did, these things are great. At first I thought there wouldn't be enough adjustment to get the mill level on my uneven garage floor, but, there was plenty, and no tools needed. They have a ratcheting lever that pulls out for adjusting and , as far as easy, well, my son was visiting this past weekend (lives 3 hrs. away) and hadn't seen the casters yet. He made his wife come out to see how easily they adjust and, well, the next morning I was out re-leveling the mill. One final THANK YOU to Coolidge and the kind forum members, and I'll move on.

Now, one last step, and my mill would be ready. Obviously, I wasn't going to be able to use the shop crane, as the base was much to wide to fit between its legs. These next pics show how I got it up 14" off the floor in order to roll the base under, and bolt them up. One note here, I'll be the first to admit, these pics look a little scary, safety wise, but, I assure you, all was very solid. Each lift with the bottle jack was only 1 1/2" (thickness of a 2X4) at a time, and all cribbing was secured to the one below it with deck screws. In fact, I felt confident enough about it that I left it up on the cribbing for 2 days. OK, I'll be honest. It wasn't by choice, after spending an afternoon crawling on the concrete floor, to get it up there, it took 2 days for this old man's bones to recuperate.

Then, it was just a matter of placing it, with it's back against the back of my Logan 2557 lathe. They both share a set of 2X4 studs that come down from rafters to floor with all my electrical outlets, as well as the VFD on the lathe side, and soon a clamp set on the mill side. I made the 2X4 "wall" frame 24" apart to mount a metal cabinet for lathe tooling, but since getting the mill, decided that the light from the window was more beneficial, so took the cabinet down, and will put shelves between the studs. Last pic Is where it will stay and get used. Oh, and I will probably paint the bare wood and red cabinets you see in some of the pics (pretty mill needs pretty surroundings?) but then again, last pic was taken 2 weeks ago, and today, its all oily, with chips everywhere. So painting isn't a priority (function over form).

Sorry this has been so long, but I need to share some thoughts. First off, I must brag. I took a chance making the base a full 12" high, but it is perfect for me, and as for stability, well, if during an earthquake, it falls over, I guarante you, it will be from the house falling on top of it. The mill seems perfect to me, but remember I've never run a mill, ever. I've been mostly practicing with facing, cutting a slot or two, and drilling holes in scrap. I used it enough to break it in well, and changed the gear head oil, with quality oil. Haven't seen any leeks, and the table and head move very smooth. Not sure what else I should be saying about it, other than I love it! Have been spending most of my time with it. Believe it or not, I needed a 5/8" set screw for something, and rather than drive 2 miles and pay maybe ? a buck fifty ? , I spent a fun afternoon, making one out of a cut off bolt, and roughed out the hex hole for the allen wrench in the top. Silly, yes, but lots of fun . I'm sure there are other things that I should be commenting on, so please reply, with any questions. I am coming up with some newbe questions, but will ask them in other threads. Thanks for taking the time to share my excitement, JR49