- Joined

- Mar 21, 2016

- Messages

- 251

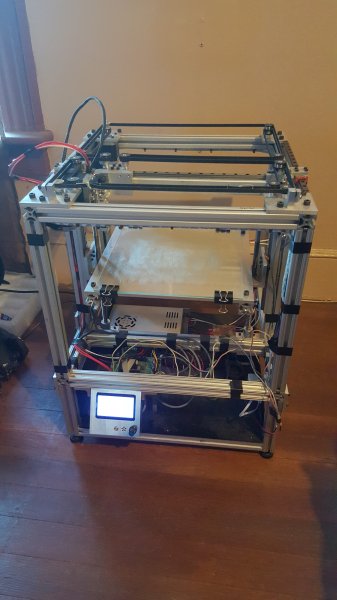

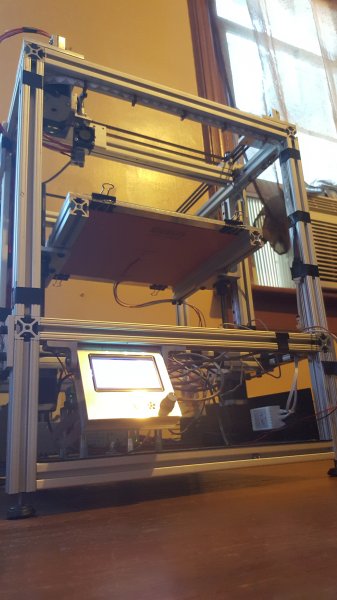

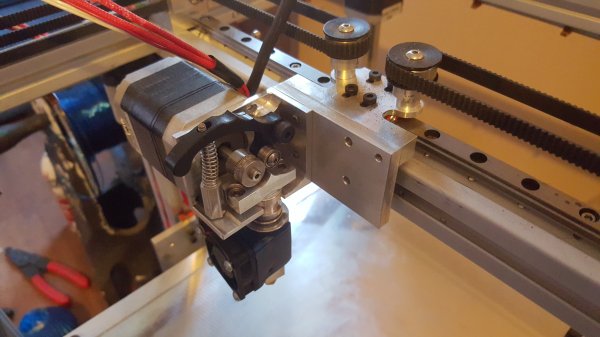

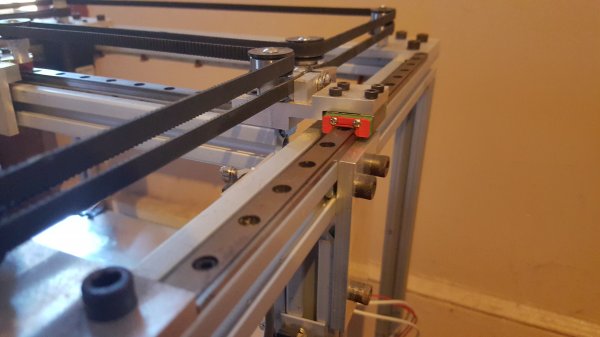

I'll never claim to be a really good machinist, and I certainly can't say i'm any good at 3d printing, but you'll never get better unless you do it. So in the spirit of learning I decided to make my own printer. And by make, I mean design from scratch and machined it myself. So anything that looks custom machined, absolutely is. Now I can't take all the credit, my brother Chris designed the belt drive routing and help machine a few of the parts, so my hat's off to him. It runs off the Marlin software which I have configured for my application. It's also got a lot of cool things like:

- integrated limit switches

- AC mains heat bed

- 24Vdc nozzel heater

- linear ball bearing slides on all axis

- double lead screw design for the Z axis table

- mic6 build platform

- and of course the cool LCD display!

If any one wants build photos i'll be happy to upload some later, but for now enjoy the (mostly) finished photos.

- integrated limit switches

- AC mains heat bed

- 24Vdc nozzel heater

- linear ball bearing slides on all axis

- double lead screw design for the Z axis table

- mic6 build platform

- and of course the cool LCD display!

If any one wants build photos i'll be happy to upload some later, but for now enjoy the (mostly) finished photos.