on my lathe the spindle gear IS part of the cone pulley...but this clears up a LOT for me thank you! I'll post some pics of the countershaft shortly.No, the bull gear is fixed on the spindle. The small spindle gear (sold and numbered as though it were a part of the cone pulley) apparently sits up against the thrust bearing. Assuming that all else is the same as on the 618 (except for the absence of a collar with set screws between the bearing and gear), the clearance between the bearing and gear should be 0.003" to 0.005". Apparently, that clearance is set by loosening the set screw in the bull gear and sliding the bull gear towards the pulley. And unlike with all of the roller bearing headstocks except the 6" MK2, you can actually use a feeler gauge to set it. Slide a 0.003" feeler gauge down between the small gear and the thrust bearing, hold the bull gear against the pulley, tighten the set screw, and confirm that the clearance is less than 0.006"

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Just started reconditioning a pretty decent 101.07301 have some questions for the experienced!

- Thread starter makeparts

- Start date

- Joined

- Dec 25, 2011

- Messages

- 10,511

OK.

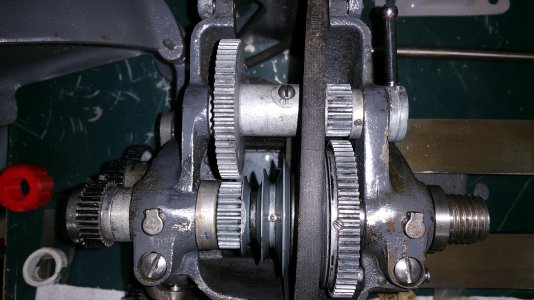

While you have your camera out, take a top view photo of the headstock on the 101.07301 showing spindle and back gears with everything installed except the belt guard. I have never come across such a photo. It would clearly show that there isn't any sleeve bearing equivalent to the M6-89 collar. Also, something to show if possible how the fixed and rotating parts of the thrust bearing are forced to be fixed and rotating, if there is any such thing.

While you have your camera out, take a top view photo of the headstock on the 101.07301 showing spindle and back gears with everything installed except the belt guard. I have never come across such a photo. It would clearly show that there isn't any sleeve bearing equivalent to the M6-89 collar. Also, something to show if possible how the fixed and rotating parts of the thrust bearing are forced to be fixed and rotating, if there is any such thing.

- Joined

- Dec 25, 2011

- Messages

- 10,511

Also, thanks for confirming that on the 6", the spindle cone pulley and small spindle gear are one piece. That isn't the case on the 10" and all of the 12". So it wasn't clear on the 6" whether the pulley and gear were actually cast as one piece or that you just couldn't buy the separate parts..

I must have perhaps a newer version, as it's part numbers M6-20B, and M6-21...I think this is the one that hangs down, if Im not mistaken.Makeparts,

Sounds as though a previous owner didn't believe in ever oiling anything. If you have time, maybe after you have rebuilt the countershaft assembly but before you have started trying to install it, could you take a photograph of it looking at it from the tailstock end but as though you were standing in front of the tailstock, so that it shows part of the front surfaces just a little?

Assuming that it is the first countershaft revisions (second version) the bracket should be L9-20A and the hanger assembly (includes the cone pulley) should stick up above the bracket instead of hanging down like the third version.

Attachments

I'll get the downfacing headstock image in a bit - here are some pics of the bearing...OK.

While you have your camera out, take a top view photo of the headstock on the 101.07301 showing spindle and back gears with everything installed except the belt guard. I have never come across such a photo. It would clearly show that there isn't any sleeve bearing equivalent to the M6-89 collar. Also, something to show if possible how the fixed and rotating parts of the thrust bearing are forced to be fixed and rotating, if there is any such thing.

the rotating race protrudes from the body, with a smaller race OD, on the side of the bearing with a bevel in the outer casing. this faces the tailstock.

the stationary race that sits against the left inner face of the headstock has a larger OD, and the casing doesn't have the same pronounced bevel, and also protrudes slightly from the outer casing.

you can see the rotating race in the pic with the 2 bearings, and the stationary race is in the other pic, with the single bearing shown on it's edge

(the races have slightly different ID's which I think are meant to provide the thrust on the spindle?). If you look earlier in the thread, the NICE bearing drawings from Clausing show this detail.

Attachments

Last edited:

- Joined

- Dec 25, 2011

- Messages

- 10,511

Yes, that is the third version, shipped with most 618's but for some unknown reason, not with the 101.07301. The hanger assemblies are the same. And the third version seems to be much easier to find than the second shorter version. It will work fine with the 101.07301, and we have the bench-mounted installation instructions for it. The only maybe disadvantage is that a larger diameter motor may fit under the 2nd version but I'm not certain of that.

I did some playing around to mock it up - I think I can make it work with my larger motor. I would have preferred the other version but that's ok...Yes, that is the third version, shipped with most 618's but for some unknown reason, not with the 101.07301. The hanger assemblies are the same. And the third version seems to be much easier to find than the second shorter version. It will work fine with the 101.07301, and we have the bench-mounted installation instructions for it. The only maybe disadvantage is that a larger diameter motor may fit under the 2nd version but I'm not certain of that.

- Joined

- Dec 25, 2011

- Messages

- 10,511

I can see an M6-253 Collar to the right of the back gear. Is there another one to the left of it? And are there two M6-255 Fiber Washers, one at either end of the back gear, or only one as some of the parts drawings show?

Yes, there is an M6-253 collar on the back gear shaft, at the left end, inside the headstock. I also added 2 of the 4 M5-255 fiber washers I purchased at the left end for spacing, but I may move 1 of them - put it at the right end...I haven't really played with the final positioning of the headstock parts yet. I'll add another top down pic of the headstock, taken more to the change gears end, to show that stuff, later today if I can.I can see an M6-253 Collar to the right of the back gear. Is there another one to the left of it? And are there two M6-255 Fiber Washers, one at either end of the back gear, or only one as some of the parts drawings show?