- Joined

- Aug 29, 2019

- Messages

- 515

I have a Snap-On YA-205 mig welder that I am trying to repair. It is another victim of the Mud Dauber gang. I will not go into detail of how I hate the little Mud Demons just to say they are totally destructive. The welder was working fine and thanks to them they packed mud in places that should not have mud. So now I am after several years about to tackle the job again this winter. I am going to try to post the pdf file to the control schematic and as you will see the parts list on the left at the bottom and on the right is some Electronic lingo that is past being Greek to me. Hopefully someone is going to pity me and explain what that actually means. These welders were originally built by Century

Electric a division of Lincoln. But like anything else with time on it all the old guys have either left the companies or passed on.

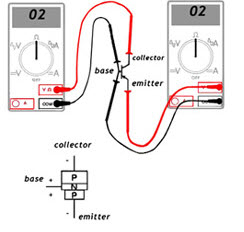

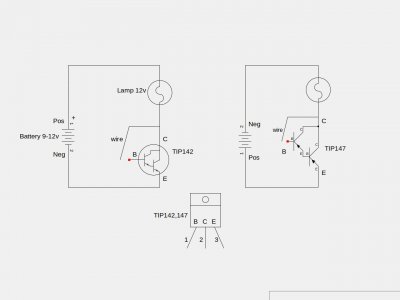

The original problem was it would not feed wire. I talked to the rep at Century, and he told me to replace a transistor which I did and then it blew the main power fuse. Not sure why it blew the fuse but I am sure I can track that down easy enough, but I do need help understanding the Electronic Lingo. Hope the pdf file helps.

Electric a division of Lincoln. But like anything else with time on it all the old guys have either left the companies or passed on.

The original problem was it would not feed wire. I talked to the rep at Century, and he told me to replace a transistor which I did and then it blew the main power fuse. Not sure why it blew the fuse but I am sure I can track that down easy enough, but I do need help understanding the Electronic Lingo. Hope the pdf file helps.