- Joined

- Jan 20, 2018

- Messages

- 5,693

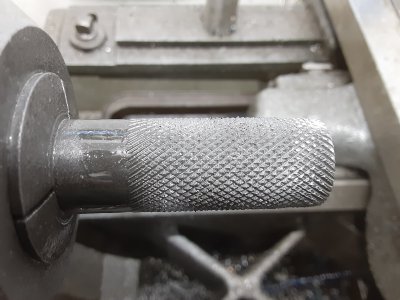

I've grown tired of fighting bump knurling, so it's time for a scissor type knurling tool. After shopping a little I decided to make my own. I started with one of these imitation Kant-twist clamps.

At less than $7 ea., I figured I could afford to sacrifice one. It needed to be wider inside to accommodate the 3/8 wide knurling rolls, so I took it completely apart and fabbed replacements for all of the pivots, nuts and spacers. While I was at it, I increased the thread to 5/16-18.

Here it is just mocked up, I still have some things to do before it gets riveted back together.

Despite working all the details on the fly, I only made one mistake and it took less than a minute to recover.

It was a good day.

(4) NEW 2" Kant Twist Type Clamps I-299 | eBay

Good Usable Condition: "Item may have marks, dents, imperfections but which do not compromise performance/functioning.".

www.ebay.com

At less than $7 ea., I figured I could afford to sacrifice one. It needed to be wider inside to accommodate the 3/8 wide knurling rolls, so I took it completely apart and fabbed replacements for all of the pivots, nuts and spacers. While I was at it, I increased the thread to 5/16-18.

Here it is just mocked up, I still have some things to do before it gets riveted back together.

Despite working all the details on the fly, I only made one mistake and it took less than a minute to recover.

It was a good day.