- Joined

- Dec 28, 2022

- Messages

- 253

Brand new EISEN 1440EV lathe.

Delivery guy (and lathe) almost toppled off lift gate. HE did fall off, but SOMEHOW the pallet jack and lathe stopped.. teetering back and forth. We finally got it to the ground with the help of some straps and a maybe even some prayers. I thought I was going to watch a man get crushed. Not a nice thing.

He put the lathe into the garage, had me sign the papers, and started walking away - I stopped him and put $100 in his hand. He said No, and tried giving it back to me. I said no way man, you came real close to death today, it’s the least I can do. He argued some more saying how about just $20 bucks…. I said just take it and thank you for what you did for me today. He finally did. He was a bit rushed to get out if there, can’t blame him.

I get into the garage and take the top off of the immaculate, looking crate. Crap, the headstock is facing the wrong way… instead of listening to my gut, and being the type that doesn’t like to leave things unfinished for some stupid reason, I did NOT go to work and get a pallet jack to maneuver it around. My reasoning behind this, was, I had purchased some machine skates, and a steering skate. I proceeded to cut the “pallet” away and get the lathe set on the skates. I then proceed to start inching the lathe around… it’s slipping on the skates, the skates are trying to turn opposite ways…. After another hour or two I almost have the machine fully turned 180 degrees…. Almost… there…. Just a little…..

OH NO!!!!! NNNNOOOOOOOOOO!!!!!!!!!!

A skate hit a low spot in the concrete that had a crack in it…. I see the lathe start to slowly tip to the long side of the 3 wheel steering skate…. (The tipping point of no return on a lathe is a LOT sooner than one would expect)

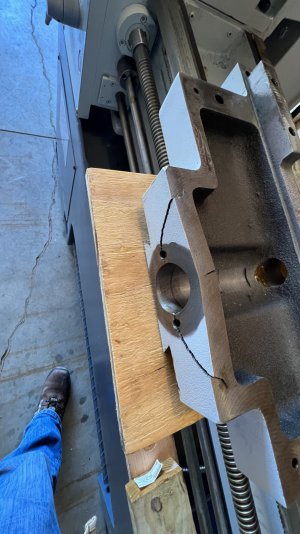

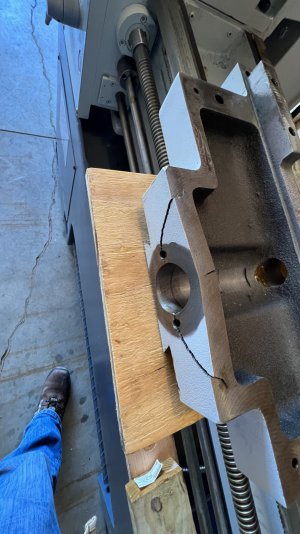

It tipped on its face…. Not the back, no… on its face….

I gather myself somewhat and start looking, or at least trying to look to see what kind of damage I just did.

The red is starting to fade from my vision and I see that the headstock has taken out a leg of my bench and currently has it pinned against a milk crate with a bunch of probably mostly useless stuff one has saved in the garage… it’s OFF the floor… Well, that’s good. I see ah handle end for the gears is all busted in pieces on the floor, but the handle seems ok - maybe a little bent towards the headstock but not horrible.

Where is that oil coming from??? I do some more looking and I see the cross-slide hand wheel is on the ground and seems to be holding the bulk of the lathe off the floor. That is where the oil is coming from, the top of the apron is open enough to let oil out…

Everything else seems to be ok - I’ll need to verify once I get it righted…. How the hell am I going to do that? I hav le nothing that will safely lift a lathe from almost flat off of the floor. I message a coworker thinking I remember him saying he had a skid steer. He does rigging and heavy lifting at work for our production lines and large ovens… I get in touch with him, and also talk to him the next day at work. He said it’s only 2300 pounds? No problem. He’s fairly busy with side jobs but he’ll see what he can do.

Why didn’t I just call him in the first place? No clue. We’re not close, we’re not friends, we just work at the same plant. He does our vacuum welding, and some maintenance stuff and I work in the office. We do talk from time to time though. Maybe more after this.

We get it righted and mostly in place. I still need to leave room to get the electrical put in. I do more inspections and find that the only real damage is to the saddle for the cross-slide and compound and the hand week assembly…WOW…. That could have been so much worse.

I need to get in touch with Eisen this coming week and see how much this is all going to cost. At least it isn’t another new lathe…

Moral of the story - get some heavy duty lifting equipment and lift it instead of trying to use less than adequate skates. You don’t know what you don’t know. And that’s typically a lot regardless of how much the ad says the skates can move.

Delivery guy (and lathe) almost toppled off lift gate. HE did fall off, but SOMEHOW the pallet jack and lathe stopped.. teetering back and forth. We finally got it to the ground with the help of some straps and a maybe even some prayers. I thought I was going to watch a man get crushed. Not a nice thing.

He put the lathe into the garage, had me sign the papers, and started walking away - I stopped him and put $100 in his hand. He said No, and tried giving it back to me. I said no way man, you came real close to death today, it’s the least I can do. He argued some more saying how about just $20 bucks…. I said just take it and thank you for what you did for me today. He finally did. He was a bit rushed to get out if there, can’t blame him.

I get into the garage and take the top off of the immaculate, looking crate. Crap, the headstock is facing the wrong way… instead of listening to my gut, and being the type that doesn’t like to leave things unfinished for some stupid reason, I did NOT go to work and get a pallet jack to maneuver it around. My reasoning behind this, was, I had purchased some machine skates, and a steering skate. I proceeded to cut the “pallet” away and get the lathe set on the skates. I then proceed to start inching the lathe around… it’s slipping on the skates, the skates are trying to turn opposite ways…. After another hour or two I almost have the machine fully turned 180 degrees…. Almost… there…. Just a little…..

OH NO!!!!! NNNNOOOOOOOOOO!!!!!!!!!!

A skate hit a low spot in the concrete that had a crack in it…. I see the lathe start to slowly tip to the long side of the 3 wheel steering skate…. (The tipping point of no return on a lathe is a LOT sooner than one would expect)

It tipped on its face…. Not the back, no… on its face….

I gather myself somewhat and start looking, or at least trying to look to see what kind of damage I just did.

The red is starting to fade from my vision and I see that the headstock has taken out a leg of my bench and currently has it pinned against a milk crate with a bunch of probably mostly useless stuff one has saved in the garage… it’s OFF the floor… Well, that’s good. I see ah handle end for the gears is all busted in pieces on the floor, but the handle seems ok - maybe a little bent towards the headstock but not horrible.

Where is that oil coming from??? I do some more looking and I see the cross-slide hand wheel is on the ground and seems to be holding the bulk of the lathe off the floor. That is where the oil is coming from, the top of the apron is open enough to let oil out…

Everything else seems to be ok - I’ll need to verify once I get it righted…. How the hell am I going to do that? I hav le nothing that will safely lift a lathe from almost flat off of the floor. I message a coworker thinking I remember him saying he had a skid steer. He does rigging and heavy lifting at work for our production lines and large ovens… I get in touch with him, and also talk to him the next day at work. He said it’s only 2300 pounds? No problem. He’s fairly busy with side jobs but he’ll see what he can do.

Why didn’t I just call him in the first place? No clue. We’re not close, we’re not friends, we just work at the same plant. He does our vacuum welding, and some maintenance stuff and I work in the office. We do talk from time to time though. Maybe more after this.

We get it righted and mostly in place. I still need to leave room to get the electrical put in. I do more inspections and find that the only real damage is to the saddle for the cross-slide and compound and the hand week assembly…WOW…. That could have been so much worse.

I need to get in touch with Eisen this coming week and see how much this is all going to cost. At least it isn’t another new lathe…

Moral of the story - get some heavy duty lifting equipment and lift it instead of trying to use less than adequate skates. You don’t know what you don’t know. And that’s typically a lot regardless of how much the ad says the skates can move.