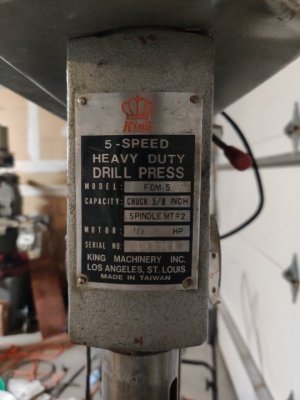

So I acquired an old "King Machinery" 5-speed drill press (FDM-5) for next to nothing (which is roughly what it's worth, in my inexpert opinion). The handles for raising and lowering the spindle are... well, two don't exist, and calling the third "rough" would be giving it way too much credit.

First, what are the odds I could just buy three handles with knobs and call it a day? I'm the farthest thing from an expert, though, so identifying the threads in the first place could be a challenge. I'm reasonably confident they're 12 TPI, and I measured the major diameter at .485, so I guess that makes 9/16-12 the most likely candidate?

If that's unlikely, I could, I guess, use some threading practice. The holes in the... whatever it's called... are also in rough shape, so I guess I could make my threads oversized and attempt to tighten things up a bit. Is a rank amateur like me likely to be successful in a job like this?

Lastly, a bizarre situation. The... handle-base... seems to be two parts; the complex part with the splines and stuff, and the "cap" part that the handles thread into, which also includes the "track" that the depth stop sits in. This "cap" is hollow, and the one handle threads far enough in that it goes past the threads and just sorta... flops around in there. Am I to assume that if all three handles were present, they'd tighten up against each other inside there, or is there further damage/missing parts?

First, what are the odds I could just buy three handles with knobs and call it a day? I'm the farthest thing from an expert, though, so identifying the threads in the first place could be a challenge. I'm reasonably confident they're 12 TPI, and I measured the major diameter at .485, so I guess that makes 9/16-12 the most likely candidate?

If that's unlikely, I could, I guess, use some threading practice. The holes in the... whatever it's called... are also in rough shape, so I guess I could make my threads oversized and attempt to tighten things up a bit. Is a rank amateur like me likely to be successful in a job like this?

Lastly, a bizarre situation. The... handle-base... seems to be two parts; the complex part with the splines and stuff, and the "cap" part that the handles thread into, which also includes the "track" that the depth stop sits in. This "cap" is hollow, and the one handle threads far enough in that it goes past the threads and just sorta... flops around in there. Am I to assume that if all three handles were present, they'd tighten up against each other inside there, or is there further damage/missing parts?