Richard, the size of the knurl diameter you need depends on your needs. Sometimes you'll need a large knob, or you may need to knurl the end of a large piece to press fit into a hole. Can't tell you how big you need but I have not had to do anything bigger than 2" yet.

That knurler in the video is way cool and would be a neat project to do, I think.

The turret knurler you're referring to is great if you're going to do a lot of pieces of one size or within a limited range of sizes. To do all the different knurls I do in my shop, it would require me to buy 4 or 5 knurlers and that will get expensive. Not for me.

Scissors knurlers can be bought or made. Of course, if you go with an Eagle Rock then it will work well from the moment you throw it on the lathe for not a lot of money. The K1-44 is the heavy duty model with the set screws holding the knurling pins and if you go for an Eagle Rock, go for that series as

@pstemari said. This is the tool you will find in many pro shops, for good reason. The thing that makes this tool worthy is the solidity of the design. Unlike the knock offs of this tool, the Eagle Rock doesn't have a lot of lateral play in the arms once it is locked down and that makes a big difference in the quality of your knurls.

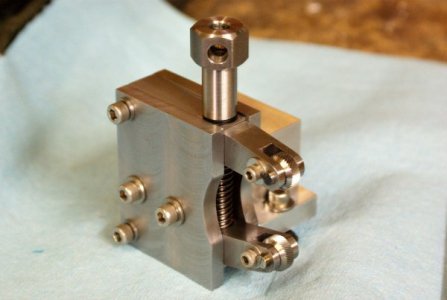

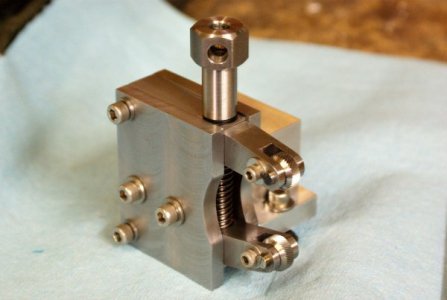

A shop-made scissors knurler is potentially much cheaper and can be made either simply or very complicated, like Doug's one in the video. I tried several designs and the one I settled on has side plates to limit lateral movement of the arms. This matters to me because most of the knurls I make are wider than the knurl itself so I have to do some axial running down the work piece; I do not want the arms to be able to move around when I do this.

The fastest way to get going is to buy one. Knurling is a high pressure operation and I suggest you buy a good tool from the get go. If you can fabricate and wish to make your own then look at the many designs out there and go for it. I made mine from a single picture much like that above and figured out how to build it.