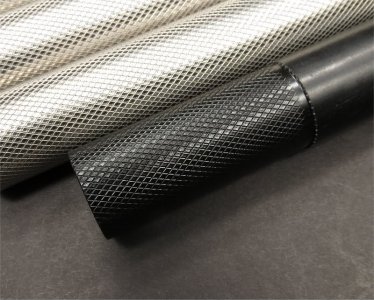

I knurl on the CNC lathe (+ stepper controlled spindle) using a sharp grounded HSS pin or a Dremel and a V-bit. The knurls are made line by line. I can change the angle, pitch and knurl depth to make different patterns but I always use the same setup: 45°, 1.4 mm pitch, 0.15 mm cd. It is slower than using a knurling tool but the result is predictable and always OK on any diameter. Knurling steel, brass, aluminium, delrin, nylon, teflon, UHMPE, etc is no problem.

You could also do a left and right hand (multi start) thread on a manual lathe if you don't care about how it looks.