- Joined

- Mar 25, 2013

- Messages

- 4,617

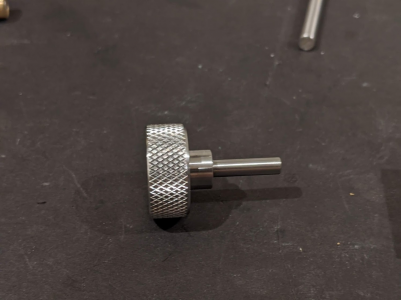

I am using a diametral pitch convex knurl on SS barstock that is 1" diameter. I am getting double or triple tracking. I assume I need to take off material? In what increments should I take down the radius/diameter? Is there an OD that would be expected to track correctly with a coarse DP knurling wheel?

Robert

Robert