- Joined

- Dec 2, 2016

- Messages

- 234

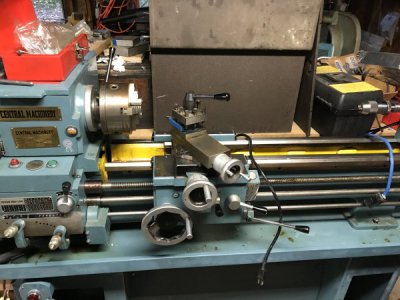

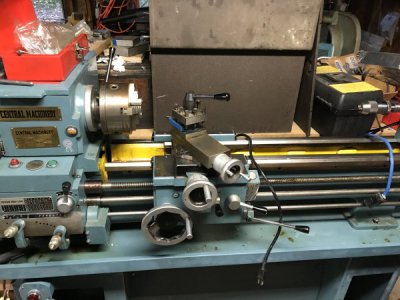

Just picked these up. Apparently they were bought in 1986 and never used, there were a few chips on the tray but according to the story they had been sitting in a garage after purchase and just never used. A lot of the cosmoline was still on the ways and attachments.

I got the for 425$ each and the lathe has everything, 4 jaw, three jaw, 5c, face plate, drill chucks, centers cutters. The mill has an indexing head, cutters, R8 collets, crap vices.

I just have not found anything about the lathe both are labeled Central Machinery the lathe is F1-900G the Mill is a 590.

Is there any difference in mid 80's chinese/taiwan build/iron quality than todays imports?

I got the for 425$ each and the lathe has everything, 4 jaw, three jaw, 5c, face plate, drill chucks, centers cutters. The mill has an indexing head, cutters, R8 collets, crap vices.

I just have not found anything about the lathe both are labeled Central Machinery the lathe is F1-900G the Mill is a 590.

Is there any difference in mid 80's chinese/taiwan build/iron quality than todays imports?