- Joined

- Feb 27, 2012

- Messages

- 158

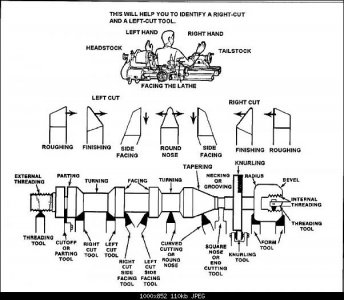

I am finally getting my lathe ready to cut. Looking at the angles of a rh tool. I am wondering what angle should the side cutting edge be at. I pretty much gather that you start about 1 1/2 times the width back, but what angle is good. I seen where Tublacain has 2/3 of the height, and I also seen only about 4 degrees. Also the front edge angle, is it 85 degrees from the cutting edge for turning, and 55 degrees for a facing too?