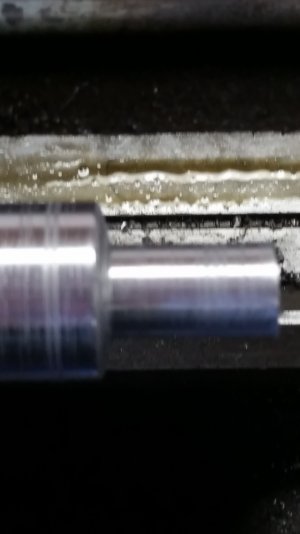

The picture below shows two significant gouges in the left and smaller ones remaining on the right. What are the typical sources of the gouges?

The stock is 1 inch mild steel. The lathe is set 500 rpm. The tool is a carbide insert 60 degree triangle. The holder is a half inch. The feed is slow and automated. Similar patterns occur from very shallow cuts up to 20 thou cuts. This surface has been sanded with 600 grit paper.

The surface is typically rough. The chips are predominately 3/4 curls. If I were to describe appearance I would describe the process more as tearing rather than cutting.

(the photo is shightly out of focus, the actual part is noticable worse then the image shows. )

Thanks in advance. Dan

The stock is 1 inch mild steel. The lathe is set 500 rpm. The tool is a carbide insert 60 degree triangle. The holder is a half inch. The feed is slow and automated. Similar patterns occur from very shallow cuts up to 20 thou cuts. This surface has been sanded with 600 grit paper.

The surface is typically rough. The chips are predominately 3/4 curls. If I were to describe appearance I would describe the process more as tearing rather than cutting.

(the photo is shightly out of focus, the actual part is noticable worse then the image shows. )

Thanks in advance. Dan