I recently purchased a 5 pc indexable lathe tool bit set. All I've ever used in the past are the standard 1/4,5/16 & 3/8 inch square HSS bits. Indexable cutters are new to me and I need help in trying to identify the different types.

View attachment 80890

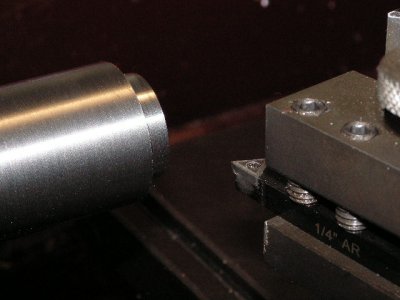

Above are four of the five bits,with these came two wrenches and extra screws.

View attachment 80891

View attachment 80894

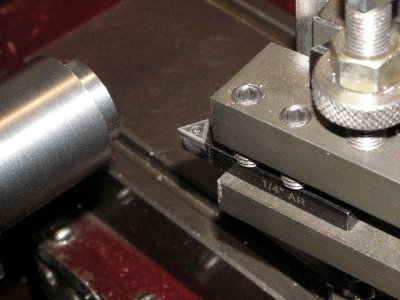

Shown above is the 5th bit much to my suprise it cuts better than anything I used in the past.

I have downloaded info from the internet one such source is the Lovejoy Tool Co. In one instance they indicate C2 is used on non ferrous metals in an other instance C2 can be used for heavy cutting and over a wide range of speeds and feeds. Are there two grades of C2? Question is,how do I find out what type of inserts came with this set. The metal used in the photos is 12L14 and I'm happy with the results. How do I order C6's or C5's? They have a "GRADE" called 908XRm and another 586XRm and it is my understanding these two parts are in the C1,C2 class

Have these designations been standardized or does every manufacturer use their own numbering system. Is there any basic info available to clarify this problem.

Any comments suggestions greatly appreciated Thanks

John Romano

View attachment 80890

Above are four of the five bits,with these came two wrenches and extra screws.

- The inserts are C2 carbide and are attached to a shank 1/4" sq 2" long

- Each are designated with the letters AL,AR,BR,BL&E (Straight) What does this mean?

View attachment 80891

View attachment 80894

Shown above is the 5th bit much to my suprise it cuts better than anything I used in the past.

I have downloaded info from the internet one such source is the Lovejoy Tool Co. In one instance they indicate C2 is used on non ferrous metals in an other instance C2 can be used for heavy cutting and over a wide range of speeds and feeds. Are there two grades of C2? Question is,how do I find out what type of inserts came with this set. The metal used in the photos is 12L14 and I'm happy with the results. How do I order C6's or C5's? They have a "GRADE" called 908XRm and another 586XRm and it is my understanding these two parts are in the C1,C2 class

Have these designations been standardized or does every manufacturer use their own numbering system. Is there any basic info available to clarify this problem.

Any comments suggestions greatly appreciated Thanks

John Romano

Last edited by a moderator: