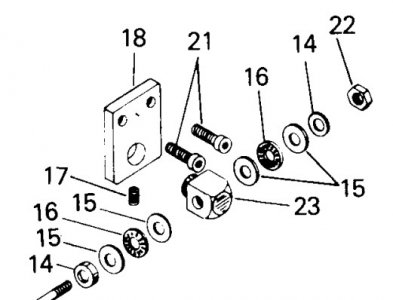

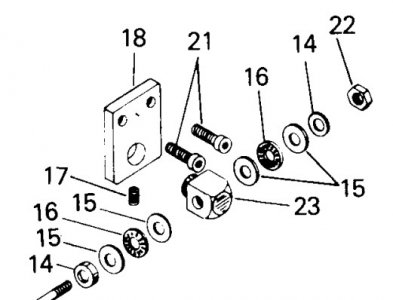

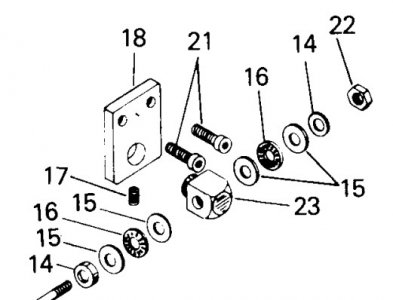

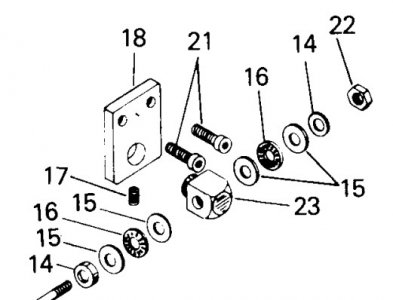

I was wondering if someone has direct knowledge regarding the lead screw support bearing using the square block, pinned against a mounting plate like Atlas used on the newer 12" lathes. The older, cast Zamak, bearing was built to break away when a collision would occur with the carriage and headstock. Looking at the pictorial, how is this style bearing meant to provide a similar protection? I need to make a replacement bearing for my 10F lathe and want to use this design. I also see two thrust bearings which I am a bit confused about, I wouldn't think that they would necessary. It's likely I'm missing something here. If someone would please give me some additional insight, it would be appreciated.

Thanks

Jim

Thanks

Jim