- Joined

- Dec 19, 2018

- Messages

- 130

Hey all,

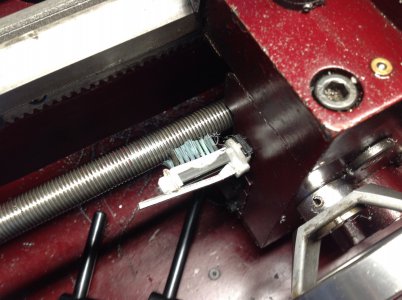

I'm concerned as to the chip contaminants that are getting on my 11x29 lathe's lead screw. Anyone have any tips on purchasing some type of expanding / collapsing guard ? I did some research, and I came up with ONE option from China, and I REFUSE to buy directly from China anymore from my last shipping clusterfuge.

I'm concerned as to the chip contaminants that are getting on my 11x29 lathe's lead screw. Anyone have any tips on purchasing some type of expanding / collapsing guard ? I did some research, and I came up with ONE option from China, and I REFUSE to buy directly from China anymore from my last shipping clusterfuge.