- Joined

- Jun 17, 2011

- Messages

- 2,062

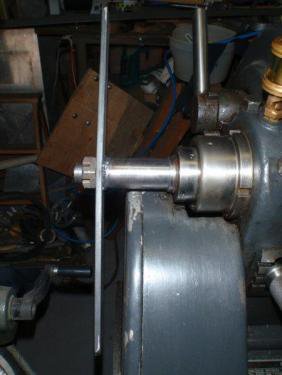

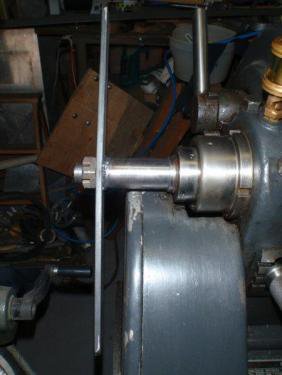

When I'm threading a short section to a shoulder, I like to turn the spindle by hand. It's easier to use a handle at the outboard end, rather than use a chuck key or wrench to turn the chuck. I have one I made for the 9" Hercus lathe, so a big one of the same design makes sense for the Storebro lathe.

The handle locks into the spindle in the same way that bicycle handlebars join the fork tube. A long wedge of tubing jams against the main tube and the sides of the spindle.

To use, insert the tube into the end of the spindle and tighten the nut. If collets are being used with a drawbar, it can be inserted through the centre of the crank.

I made the handle 14" long because that is the maximum diameter I can turn over the toes of the carriage. I have to admit, it's quite a step up to have a chuck that's 10 5/8" in diameter.

The handle locks into the spindle in the same way that bicycle handlebars join the fork tube. A long wedge of tubing jams against the main tube and the sides of the spindle.

To use, insert the tube into the end of the spindle and tighten the nut. If collets are being used with a drawbar, it can be inserted through the centre of the crank.

I made the handle 14" long because that is the maximum diameter I can turn over the toes of the carriage. I have to admit, it's quite a step up to have a chuck that's 10 5/8" in diameter.