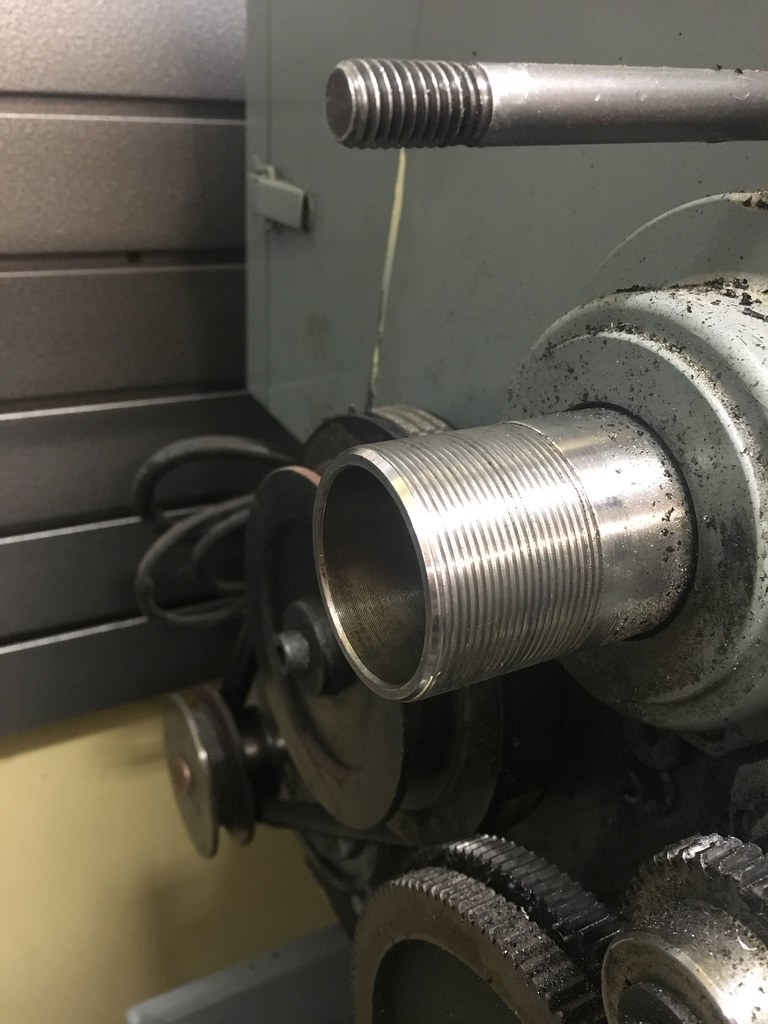

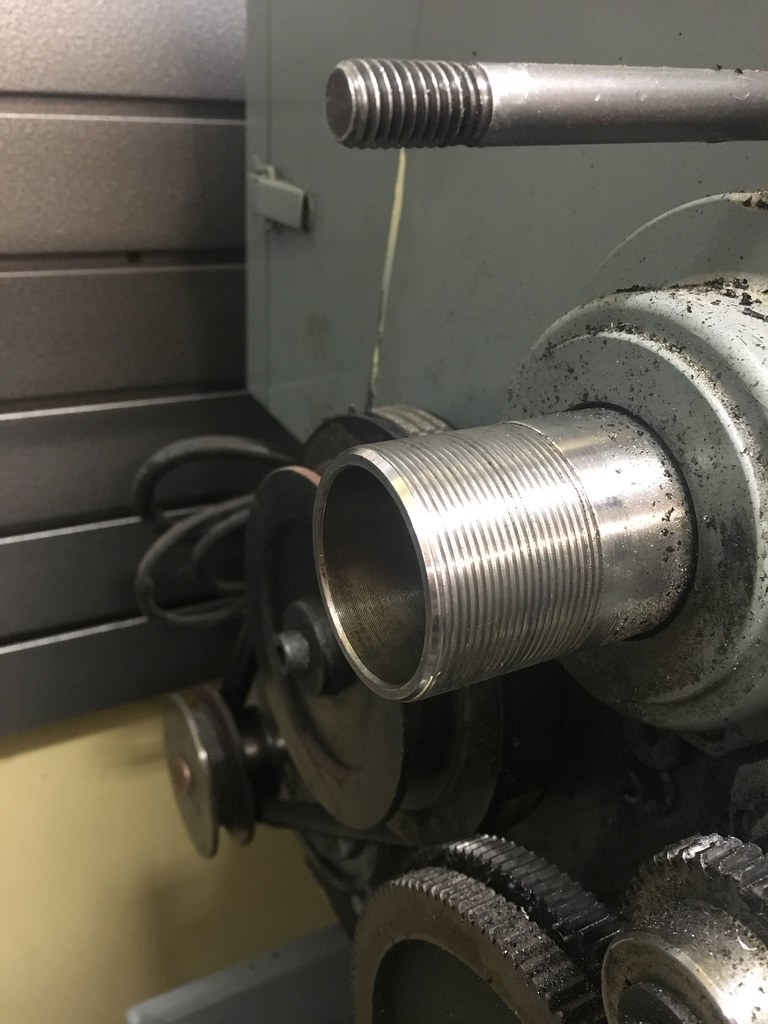

The O.D of the threads on the spindle are 1.794". and the threads are 16 TPI

I would like to try and make a female part to thread on there. to use as a stop to make repeatable long length parts, and also use as a spider

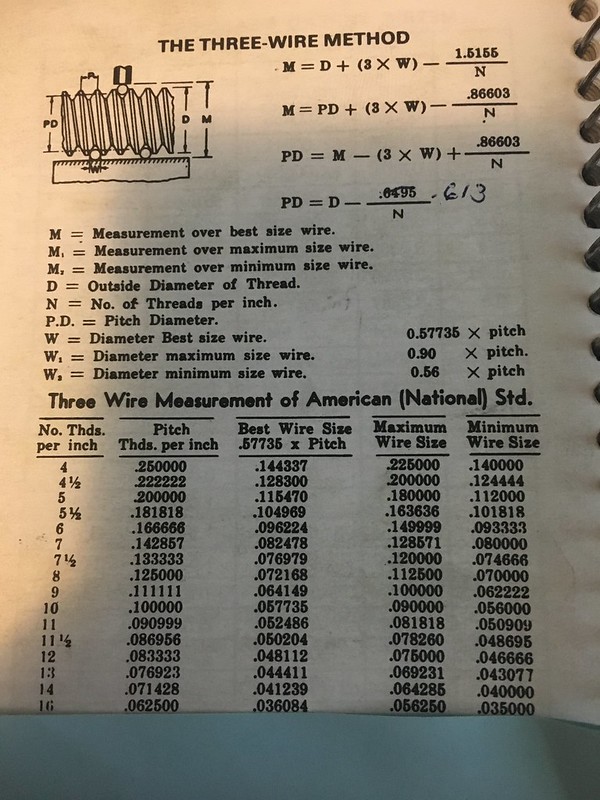

How do I calculate the best bored i.d prior to threading, and the best depth of thread cut?

my cross slide moves the actual dial measurement. (in .001. takes .002 of the diameter of the work.)

Most of the formulas I found are for external screw thread cutting.

I will not be able to test the part for fit, as I will lose my threading start place if I remove it from the chuck at any point.

I would like to try and make a female part to thread on there. to use as a stop to make repeatable long length parts, and also use as a spider

How do I calculate the best bored i.d prior to threading, and the best depth of thread cut?

my cross slide moves the actual dial measurement. (in .001. takes .002 of the diameter of the work.)

Most of the formulas I found are for external screw thread cutting.

I will not be able to test the part for fit, as I will lose my threading start place if I remove it from the chuck at any point.