- Joined

- Aug 19, 2013

- Messages

- 764

Ski, now that John and I have you completely confused, I'll try to clear that up.

First, you don't NEED the mag starter in the circuit at all, everything you want to do can be done with the drum switch. FOR/OFF/REV

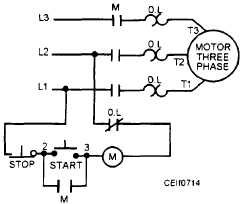

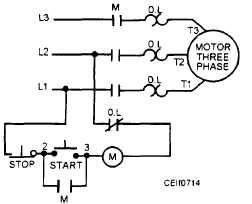

Since you have the mag starter, you MAY use it to add a little safety to the system, by adding an E-Stop button.

If you are going to add an E-Stop button, then you may as well add a Start button while you're at it.

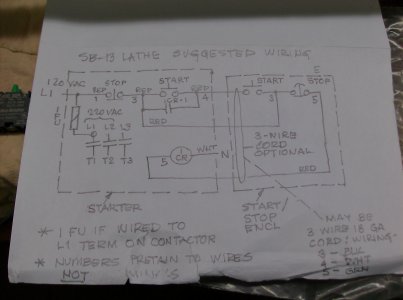

Something like this is what I have in mind.

The mag starter is already wired up to accept this kind of a switch system, there are 3 wires to connect.

You don't have to buy the entire assembly as you see it. Your local hardware store will have a suitable box. The switches are about $12 each. You could do a little scrounging and maybe come up with one from an old piece of industrial equipment.

Let us know what way you want to go, and we'll help you with the wiring.

I agree with your suggestion for the remote start & safety. I have sent a private message offering a free used start/stop NEMA enclosure to my fellow "Badger" member.