- Joined

- May 10, 2014

- Messages

- 819

In my area this object is called a trivet. I expect other areas have other names such as hot pot holder. Please comment if you have another name.

I saw this design many years ago. I was reminded at a visit to the local Woodcraft store where they had variations on this design made on a CNC machine so they had circular slots instead of straight. I do not have a CNC machine, but decided to try the straight slot lattice style I had seen so many years ago on my milling machine. I am happy with how this turned out.

A piece of red oak, about 8.5in square. The finish is just mineral oil.

A series of slots milled to half depth on one side parallel to the grain.

On the other side at right angles to the grain.

My steps below for anyone interested.

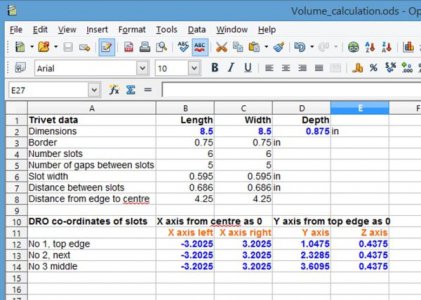

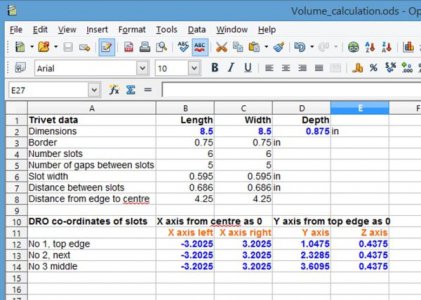

It is so easy to forget to add or subtract the cutter width when calculating co-ordinates for the DRO so I decided to make a spreadsheet since I have a few requests to make these for friends.

In my first attempt I cut the piece square on the tablesaw. I have a good mitre gauge - by woodworking standards, but the edges were slightly off 90 deg. Hence the ends of the slots did not align. For my second attempt I trimmed the edges on the milling machine as well as one face which was not flat.

I tried clamping the wood in the mill vise, but it flexed so I had to remove the vise and clamp directly to the table.

My Grizzly G1008 mill does not have the Y axis travel to be able to mill all 6 slots so I mill 3 slots then turn the piece 180 deg to mill the other 3. I am using a small square clamped to the table to register the back left corner of the work. I used an edge finder to find the edges then moved the X axis to the centre and set DRO X axis to 0. On the Y axis I used edge finder then set the rear edge to 0 on the DRO.

The spreadsheet reflects this convention. X axis co-ordinates are from centre, and Y axis from the rear edge.

After milling the first side, I flip to the other side and rotate 90 deg. First slot on the other side will show if I got the depth correct. I needed to raise the table a couple of thou for the other slots to get better "holes" from the slot intersections.

The milling completed. I kept my printout on the table. It is very easy to get confused if the co-ordinates are not written down.

There are always what I call "feathers" to be removed.

The edges were routed with 1/4in radius roundover bit.

The appearance after sanding before adding the mineral oil.

I must have messed up with the table position for the beginning of slot in the lower left. It is my "oops" and not an optical illusion.

I saw this design many years ago. I was reminded at a visit to the local Woodcraft store where they had variations on this design made on a CNC machine so they had circular slots instead of straight. I do not have a CNC machine, but decided to try the straight slot lattice style I had seen so many years ago on my milling machine. I am happy with how this turned out.

A piece of red oak, about 8.5in square. The finish is just mineral oil.

A series of slots milled to half depth on one side parallel to the grain.

On the other side at right angles to the grain.

My steps below for anyone interested.

It is so easy to forget to add or subtract the cutter width when calculating co-ordinates for the DRO so I decided to make a spreadsheet since I have a few requests to make these for friends.

In my first attempt I cut the piece square on the tablesaw. I have a good mitre gauge - by woodworking standards, but the edges were slightly off 90 deg. Hence the ends of the slots did not align. For my second attempt I trimmed the edges on the milling machine as well as one face which was not flat.

I tried clamping the wood in the mill vise, but it flexed so I had to remove the vise and clamp directly to the table.

My Grizzly G1008 mill does not have the Y axis travel to be able to mill all 6 slots so I mill 3 slots then turn the piece 180 deg to mill the other 3. I am using a small square clamped to the table to register the back left corner of the work. I used an edge finder to find the edges then moved the X axis to the centre and set DRO X axis to 0. On the Y axis I used edge finder then set the rear edge to 0 on the DRO.

The spreadsheet reflects this convention. X axis co-ordinates are from centre, and Y axis from the rear edge.

After milling the first side, I flip to the other side and rotate 90 deg. First slot on the other side will show if I got the depth correct. I needed to raise the table a couple of thou for the other slots to get better "holes" from the slot intersections.

The milling completed. I kept my printout on the table. It is very easy to get confused if the co-ordinates are not written down.

There are always what I call "feathers" to be removed.

The edges were routed with 1/4in radius roundover bit.

The appearance after sanding before adding the mineral oil.

I must have messed up with the table position for the beginning of slot in the lower left. It is my "oops" and not an optical illusion.