- Joined

- Dec 18, 2019

- Messages

- 6,447

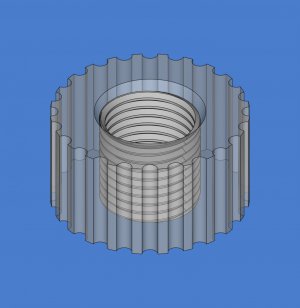

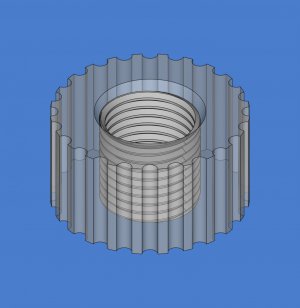

Sort of learned something the hard way today. The Fastener Workbench has a tap object, which one can use to cut female threads in an object. I chose a 1/2" tap and a custom thread of 1.27mm (20 TPI). What I got in the model, but I didn't recognize, was 1/2"-13 threads. I exported my model to stl to make a 3D print. I couldn't understand why I couldn't run a 1/2"-20 tap through the hole.

Going back to the model and TechDraw, I dimensioned the thread pitch and discovered that the thread was 1/2-13. So FreeCAD was ignoring my custom pitch, with a tap diameter selection of 1/2", and substituting in the UNC pitch, rather than my desired UNF pitch.

Back to Fastener Workbench, one can select a custom diameter and pitch. I tried that and got what I expected. Kind of irritating to have wasted the time, but I did learn that UNF is not native to FreeCAD. So printing again, and hoping to have better results!

What have I made? A protective cap for 1/2-20 UNF threads.

Going back to the model and TechDraw, I dimensioned the thread pitch and discovered that the thread was 1/2-13. So FreeCAD was ignoring my custom pitch, with a tap diameter selection of 1/2", and substituting in the UNC pitch, rather than my desired UNF pitch.

Back to Fastener Workbench, one can select a custom diameter and pitch. I tried that and got what I expected. Kind of irritating to have wasted the time, but I did learn that UNF is not native to FreeCAD. So printing again, and hoping to have better results!

What have I made? A protective cap for 1/2-20 UNF threads.