- Joined

- Sep 15, 2017

- Messages

- 55

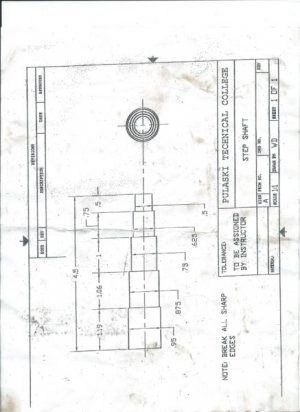

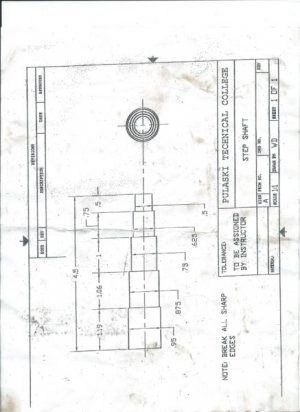

In January I began lathe (and welding) training at the local tech school. Shortly after I started, I was in an auto accident and hurt my back. I ended up dropping out completely. But not before getting the drawings for my first project. It is a simple project turning a piece of 1" round stock to 5 different diameters along it's length. It includes a facing operation, center drilling for a live center, turning and parting off. I finally felt well enough to try this on my 61 year old Clausing 6913. In class I would have been turning 12L14. At home I have some 1" A36 round stock left over from an axle I made for my nephews wagon so that is what I am using. I learned from trial and error how to set the feed rate (it does not operate smoothly), that the recommended spindle speed needs to be doubled when using carbide inserts, my cross feed has a lot of back lash, that close is not close enough when centering the lathe tool. Indicating A36 round stock with mill scale and general out of round is difficult. All I could do is get it close and trust that I could turn it the rest of the way. My first piece was pretty much just getting on the same page with my lathe and figuring out that just because the levers move, does not mean that the inner workings are going to mesh like they're supposed to. I started my second attempt this evening and my first diameter came out .003 under size (I should have let it cool down after my rough cuts). I flipped it around and indicated off of what I already turned and then faced it off. Tomorrow, I will be center drilling the end to accept my dead center. I would prefer a live center but I gotta use what I got. Then I will turn the rest of the diameters. I have lots of round stock so I can do it again and again until I feel comfortable with the different operations. I am pretty excited.