I recently picked up this Busybee mill from an estate sale. I'm very new to hobbyist machining (pardon incorrect terminology) and have started to disassemble and clean the machine prior to putting it to work. The one thing I cannot figure out is how to lock the spindle to remove the collet and tooling. It looks like the previous owner was grabbing the spindle with a pipe wrench to loosen the draw bar. I used and impact to initially get the tooling out but would like to figure out how I'm supposed to do it.

Some machinist friends think that it was manufactured for morse tapers - but was retrofitted to accept R8 collets.

The mill

Drawbar insert hole

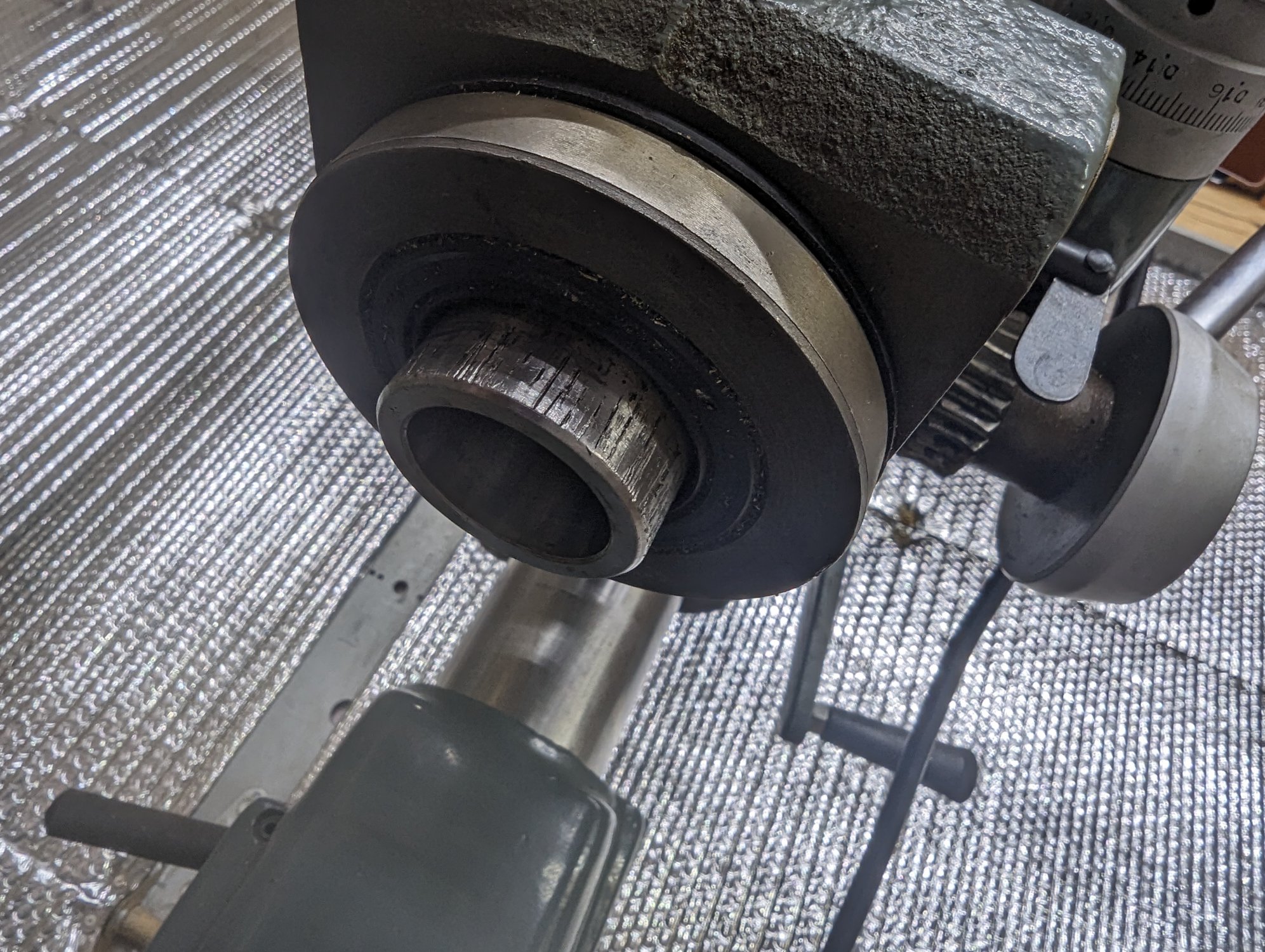

Only the inside column spins, but there is no keyway or hole for locking mechanism

Some machinist friends think that it was manufactured for morse tapers - but was retrofitted to accept R8 collets.

The mill

Drawbar insert hole

Only the inside column spins, but there is no keyway or hole for locking mechanism