Double back tape works great for that application also .

Yup have that too and an arsenal of various epoxies. It was just the Loctite that perplexed me.

Double back tape works great for that application also .

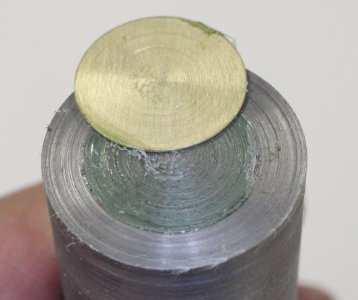

Sorry, Loctite 680 is for joining cylindrical parts. It will not work for your application…not. I would read-up on Loctite products and their proper application first. Good luck…Dave.