- Joined

- Feb 17, 2021

- Messages

- 468

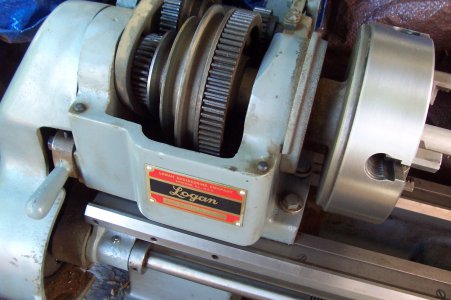

just picked up a logan 9X38 lathe that has only a 4 jaw 6 in. chuck, really dont care for that type and needing a 3 jaw. dont know very much about the machine yet

so reaching out here hoping someone can set me striaght on what to get...........pix below>>>>

so reaching out here hoping someone can set me striaght on what to get...........pix below>>>>