Pushing the envelope on forum ediquite, this is from Scott Logan posted to the board he moderates on Groups.io:

From: "Scott S. Logan" <ssl@l****.com>

Date: Mon Oct 16, 2000 7:11 am

Subject: Adapting a QC Gearbox

Received the following private message from a subscriber, but I thought it

pertinent to answer here.

> Scott, Can a Wards (Logan) 2130 lathe be fitted with a quick

> change gearbox.

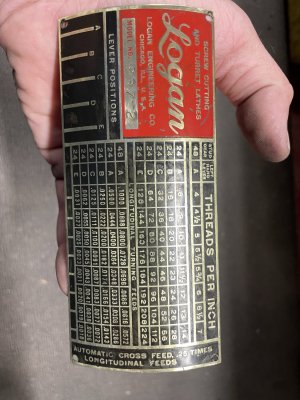

All Logan (and Wards) 10", 11" and 2900 Series 12" Lathes used the same

gearbox, after serial number 46561. The "Accessory Gearbox", as provided

for Wards Lathes or others not factory equipped, were the same as well,

with one minor modification.

Logan 10" and 11" Lathes not factory equipped with a QC Gearbox, also had a

"Plain Apron", meaning they did not have a clutch for power feeds. These

Lathes use a miter gear arrangement for power cross feeds, and rely on the

half nuts for power longitudinal feeds (in other words, power longitudinal

feeds are a very fine thread).

The aprons on such lathes are different in that the half nut is in a

different relative location.

On QC Lathes with the Automatic Apron, the Lead Screw is on the same

vertical plane as the front edge of the bed. In other words, a vertical

line drawn down from the front edge of the bed would intersect the

centerline of the Lead Screw.

On Plain Change Lathes with the Plain Apron, the Lead Screw is ~11/32"

closer to the bed wall.

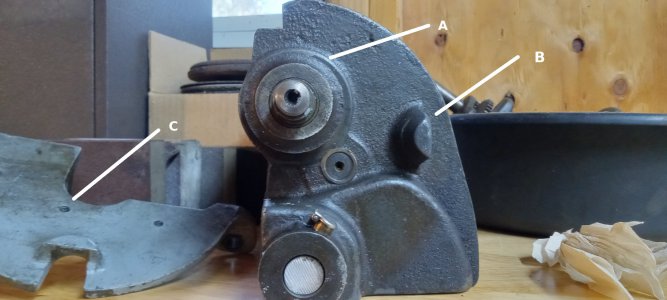

As a result, when moving a QC Gearbox from a Lathe with the Automatic Apron

to one with the Plain Apron, the mounting surface of the Gearbox must be

milled down ~11/32". The tailstock support bearing would not be changed

from the original on the Plain Change Lathe. Of course, the Lead Screw

will need to be either kept with the Gearbox, or shortened up to

accommodate the Gearbox.

Please note that Gearboxes from earlier lathes, prior to 46561, or from

2500 Series 12" Lathes, or from any 14" Logan Lathe will not be adaptable

to the 10" or 11" Plain Change Lathes. Also, the Gearbox from the 9"

Lathes are different, although the internal parts are mostly the same (the

Drive Shaft is different, as well as the box itself).

Hope this helps. If not, suggest you simply ask Scott on his board.

Ron