- Joined

- Feb 28, 2019

- Messages

- 502

I hate it when the thing you are googling for gets drowned in the noise.

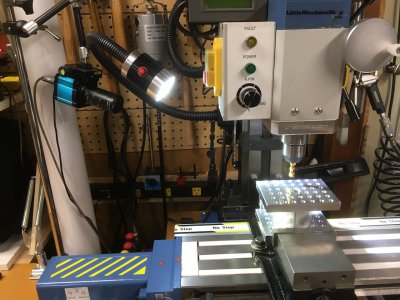

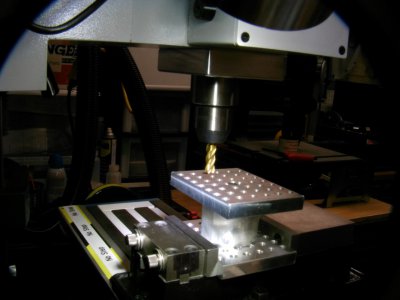

I'd like to mount a small/tiny wireless camera on my CNC so I don't need to stick my head in to try to observe stuff. I've been using my phone held by hand, works pretty good but it's still a pain to keep it zoomed in and focused.

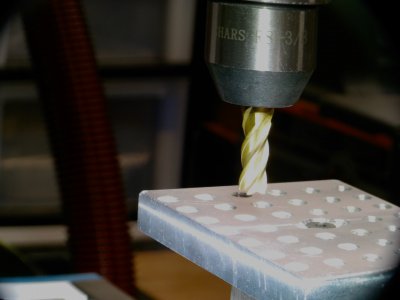

There are a million mini / micro spy/nanny cams out there - Not what I want as I need focus range to be on the order of 6".

A borescope would work, but I don't want a big long snake to deal with. I guess I could route borescope cable but it wold be really awesome to have a matchbook sized cam mounted right near the spindle that is bluetooth or WiFi

What do I need to search for to find this thing?

Tiny cameras have gotten ridiculously cheap. I'm sure this exists and is affordable, I just can't find it.

I'd like to mount a small/tiny wireless camera on my CNC so I don't need to stick my head in to try to observe stuff. I've been using my phone held by hand, works pretty good but it's still a pain to keep it zoomed in and focused.

There are a million mini / micro spy/nanny cams out there - Not what I want as I need focus range to be on the order of 6".

A borescope would work, but I don't want a big long snake to deal with. I guess I could route borescope cable but it wold be really awesome to have a matchbook sized cam mounted right near the spindle that is bluetooth or WiFi

What do I need to search for to find this thing?

Tiny cameras have gotten ridiculously cheap. I'm sure this exists and is affordable, I just can't find it.