- Joined

- May 9, 2020

- Messages

- 42

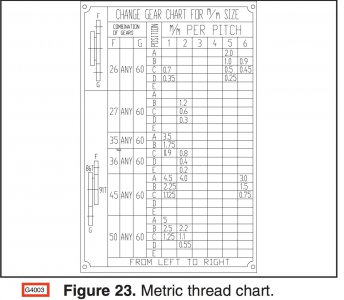

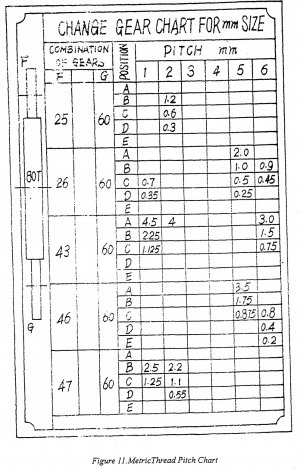

I bought a lathe a year or so ago from a woman who's husband had died. It was a great deal and I have loved learning how to use it and turn all sorts of things. Now that I want to start making threads, I have found that I am stuck with the 43 and 60 tooth change gears. It's stock gears for imperial threads is 40 and 40 which I have found from grizzly to be a match with their G4003 Lathe and have ordered them. But the rest of the change gears are different tooth count and it's proving difficult to find out what pitch, pressure angle and thickness I need. By the way, I do want to make metric threads and this is why I am looking for the 25, 26, 46 and 47 tooth gears. Any suggestions?