- Joined

- Feb 25, 2024

- Messages

- 8

First post here!

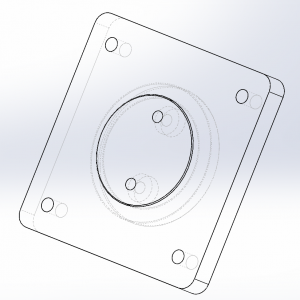

So I was gifted a ShopFox M1049 from a friend who upgraded his shop. He had taken off the compound slide and replaced it with a fixed mount because he mostly used the lathe for threading and straight boring operations. He was not able to find the original compound for this lathe. I purchased a mini-lathe compound rest from littlemachineshop (part # 1769) but its obviously a little small for this unit and it did not include the clamping ring pieces. Grizzly doesn't have the parts stocked and based on the age of the machine probably never will.

So can anyone recommend where I could purchase a full compound rest for this size lathe? I'm fine with adapter plates. Prefer something appropriate for AXA quick change tool posts.

Alternatively, I could make the bottom clamping pieces but this will be my first project and I'm thinking it might be biting off more than I can chew. I also have a cnc mini-mill but I haven't hooked it up yet. I figured the lathe would be easier.

I expect that I'll be doing mostly small and medium projects for things like RC cars and some other hobbies. I also have a young fella at work with a busted retaining pin on an airsoft rifle that I would like to make for him in brass. It's got two different taper angles on it. I think it's small enough that I could grind a tool for each angle but I don't have a good low speed grinder yet either.

Thanks for any advice. Looking forward to making some chips instead of just watching them do it on youtube!

So I was gifted a ShopFox M1049 from a friend who upgraded his shop. He had taken off the compound slide and replaced it with a fixed mount because he mostly used the lathe for threading and straight boring operations. He was not able to find the original compound for this lathe. I purchased a mini-lathe compound rest from littlemachineshop (part # 1769) but its obviously a little small for this unit and it did not include the clamping ring pieces. Grizzly doesn't have the parts stocked and based on the age of the machine probably never will.

So can anyone recommend where I could purchase a full compound rest for this size lathe? I'm fine with adapter plates. Prefer something appropriate for AXA quick change tool posts.

Alternatively, I could make the bottom clamping pieces but this will be my first project and I'm thinking it might be biting off more than I can chew. I also have a cnc mini-mill but I haven't hooked it up yet. I figured the lathe would be easier.

I expect that I'll be doing mostly small and medium projects for things like RC cars and some other hobbies. I also have a young fella at work with a busted retaining pin on an airsoft rifle that I would like to make for him in brass. It's got two different taper angles on it. I think it's small enough that I could grind a tool for each angle but I don't have a good low speed grinder yet either.

Thanks for any advice. Looking forward to making some chips instead of just watching them do it on youtube!