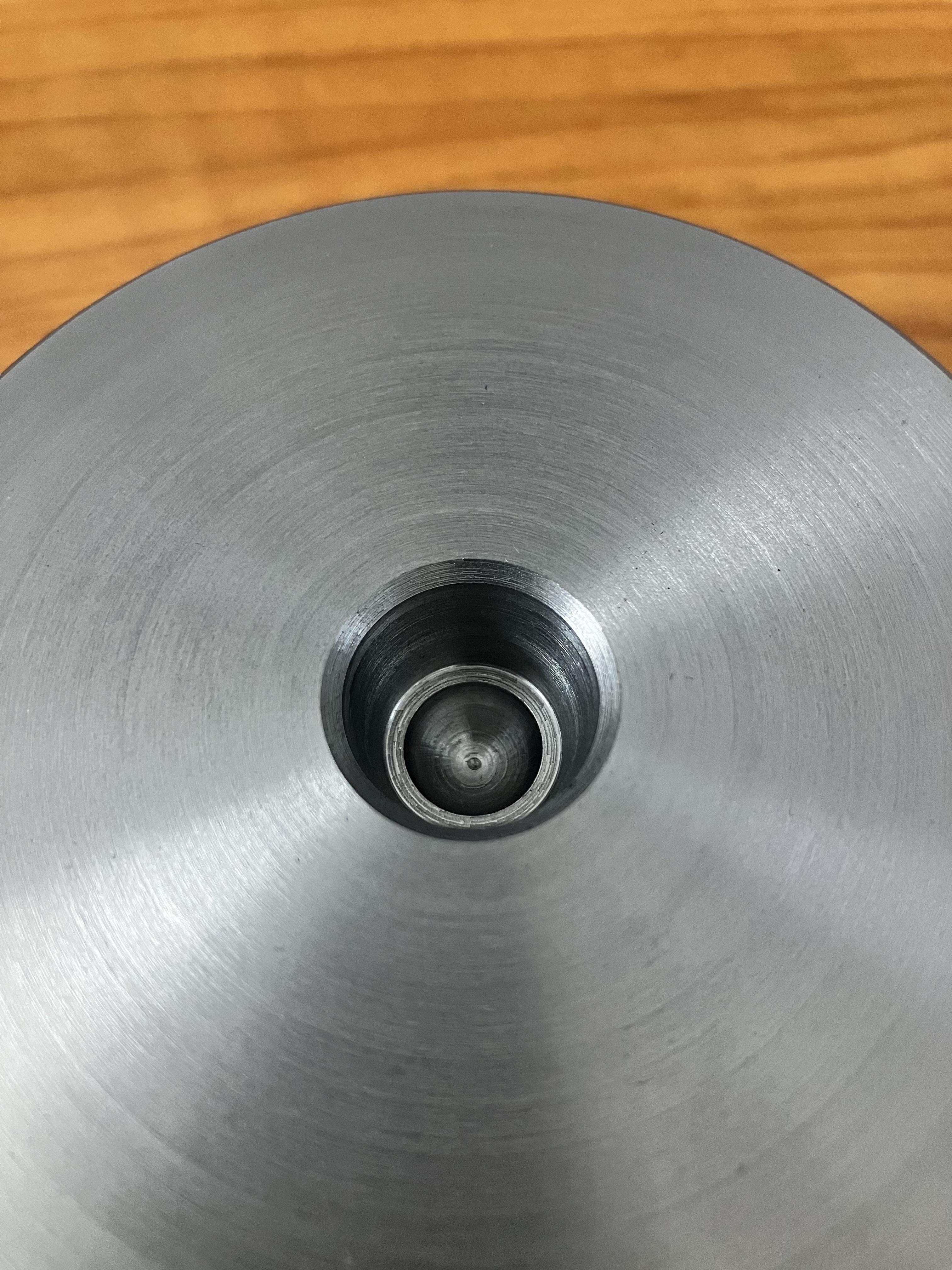

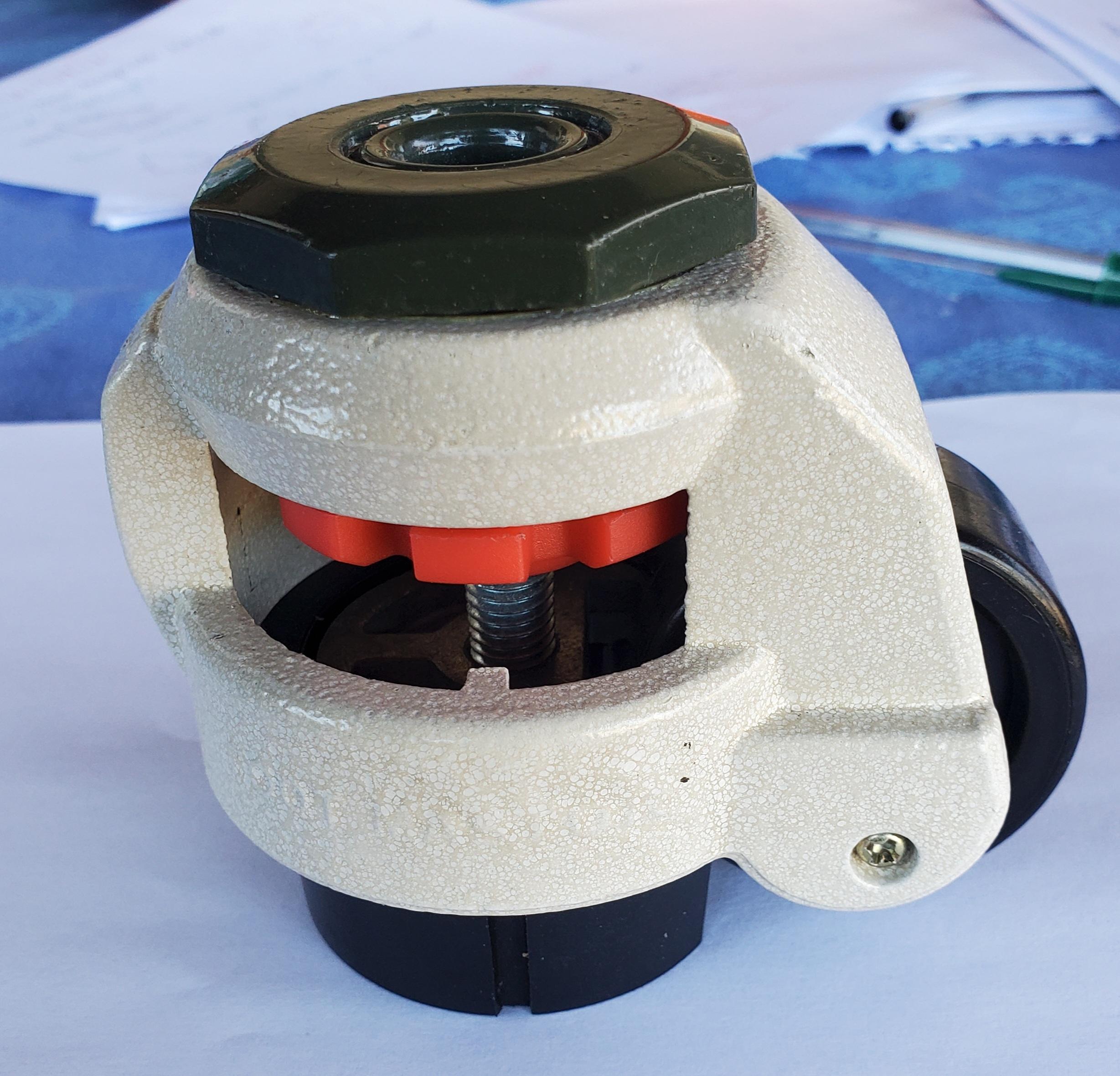

You are going to have a lot of weight on them those nobs will be hard to turn. Look at some with a ratcheting lever on them like Foot Master.

www.zoro.com

www.zoro.com

Foot Master Leveling Caster, Ratchet, 63 mm Nylon Wheel, 1/2-13 Stem, Swivel, 500 kg Cap, NBR Foot Pad, Black GDR-80-S-NYN-FBL-1/2 | Zoro

Order Foot Master Leveling Caster, Ratchet, 63 mm Nylon Wheel, 1/2-13 Stem, Swivel, 500 kg Cap, NBR Foot Pad, Black, GDR-80-S-NYN-FBL-1/2 at Zoro.com. Great prices & free shipping on orders over $50 when you sign in or sign up for an account.