- Joined

- Mar 13, 2017

- Messages

- 36

Here's a link to two of my early stocks:

http://www.hobby-machinist.com/threads/54r-aluminum-mauser-stock-project.33197/#post-312378

http://www.hobby-machinist.com/threads/mosin-rehab-project-2015.35842/#post-338008

You're going to find that you're going to need access to a rotary table for modern mag wells or going to need some special jigging to get the side tapers. Other than that it's all about basic milling and processing the cuts in the correct order so you don't cut away a surface you're going to need for clamping later on.

I previously stumbled upon your Mauser project, the finished Mosin is amazing, really love the contrasting aluminum with the OD. I'm still between OD and FDE, still can't decide.

All my tools are at school, but when roughly checking sides the Ruger magazine, which is honestly pretty janky, I found that the sides were parallel with no taper at all.

When the magazine is in the stock theres between 15 and 25 thousands of side to side play. Maybe I'm missing something in terms of mag-well taper, or did Ruger just decide the fit doesn't need to be perfect and just oversized the mag-well?

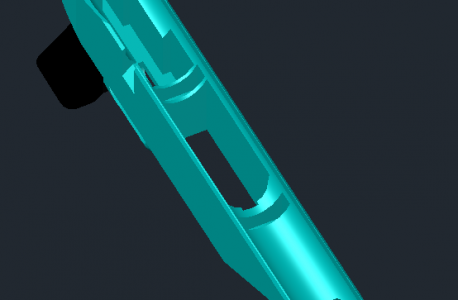

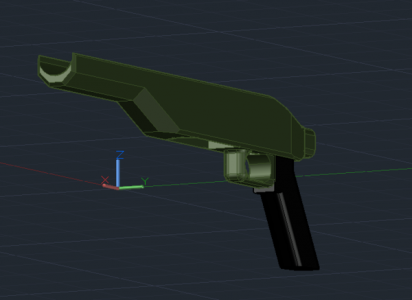

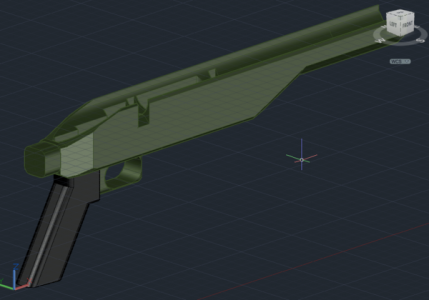

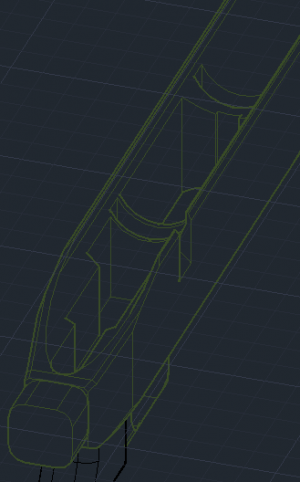

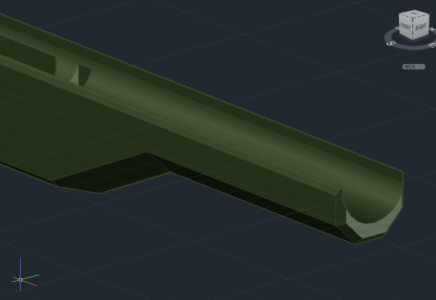

I have a long ways to go before I even start cutting anyway. I made a early stage CAD model last night, it turned out alright. I plan on adding some slots in the forend like the LSS chassis have. I'm finding I am pretty limited in terms of aesthetic features on the sides because of the slim wall thickness which is leaving me with a lot of empty boring space. Can't decide if I should increase my blank thickness or just keep it simple. I think I'm going to go with shallow flutes like in the first photo on my original post. If anyone is at some point interested in doing this project here are some photos of my CAD, shoot me a message if you are interested in the files.

Last edited: