- Joined

- Dec 30, 2021

- Messages

- 59

I recently took a stab at another project, a machinist's hammer. Ended up with a bit of hammer shaped metal that I can hit things with and lots of experience.

(brass face omitted because I made a boneheaded mistake that my pride prohibits sharing)

I think I want to remake the head because I didn't do a very good job on the hole that the handle screws into. The head is a 1" diameter cylinder, 2.5 inches long. The handle hole is tapped 1/2-20 and there's a bit of a .600 hole before the threads start to allow the handle to 'vanish' into the head. Material is 6061.

To get a flat bottom on the hole, the suggested order of operations was to:

Drill close to the minor diameter

Use a mill to mostly flatten the bottom of the hole

Use a boring bar to open the hole to the minor diameter

Use the boring bar to open that little bit of .600 hole

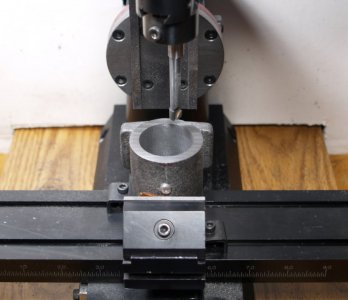

The problem was really getting a grip on the thing with the four jaw. because of the head's length, I had to reverse the jaws on the long axis of the head. Unfortunately, this raises the part off the face of the chuck and I couldn't get the jaws on the narrow axis to grip the part.

So, I tightened the long axis jaws and worked gently. The drill was no problem. I couldn't get a mill in there, I was already close to the minor diameter and was able to flatten the bottom a bit and get my minor diameter, but there was no way that setup was going to hold together for the .600 boring operation.

At the end of this experience, I said "this would probably have been trivial on the mill".

The only thing that might have been an issue is that I do not have a boring head for my mill. The Sherline offering doesn't have a good reputation around these parts and I've just caught my breath after looking at the Criterion heads everyone seems to love.

So, after that lengthy setup, two questions:

(brass face omitted because I made a boneheaded mistake that my pride prohibits sharing)

I think I want to remake the head because I didn't do a very good job on the hole that the handle screws into. The head is a 1" diameter cylinder, 2.5 inches long. The handle hole is tapped 1/2-20 and there's a bit of a .600 hole before the threads start to allow the handle to 'vanish' into the head. Material is 6061.

To get a flat bottom on the hole, the suggested order of operations was to:

Drill close to the minor diameter

Use a mill to mostly flatten the bottom of the hole

Use a boring bar to open the hole to the minor diameter

Use the boring bar to open that little bit of .600 hole

The problem was really getting a grip on the thing with the four jaw. because of the head's length, I had to reverse the jaws on the long axis of the head. Unfortunately, this raises the part off the face of the chuck and I couldn't get the jaws on the narrow axis to grip the part.

So, I tightened the long axis jaws and worked gently. The drill was no problem. I couldn't get a mill in there, I was already close to the minor diameter and was able to flatten the bottom a bit and get my minor diameter, but there was no way that setup was going to hold together for the .600 boring operation.

At the end of this experience, I said "this would probably have been trivial on the mill".

The only thing that might have been an issue is that I do not have a boring head for my mill. The Sherline offering doesn't have a good reputation around these parts and I've just caught my breath after looking at the Criterion heads everyone seems to love.

So, after that lengthy setup, two questions:

- I can understand that Sherline boring head is fussy, but is there an envelope within which, it might deliver reasonable results?

- If I stayed on the lathe, is there any way I could have made the setup more rigid?