- Joined

- Jul 7, 2012

- Messages

- 641

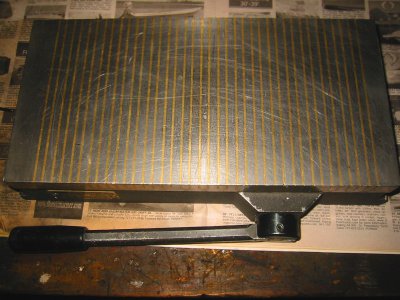

Chuck in question is the flat permanent magnet type as commonly used on a surface grinder.

Q1: In absence of said surface grinder, can the chuck face be safely trued with a face/shell mill cutter?

Q2: Segmented (aluminum/steel or brass/steel) 'V' blocks and spacers are usually used for work-piece location.

Is this (a): to prevent the work-piece from becoming permanently magnetized, or (b): to protect the magnetic chuck, or (c): some other reason?

Thanks,

M

Q1: In absence of said surface grinder, can the chuck face be safely trued with a face/shell mill cutter?

Q2: Segmented (aluminum/steel or brass/steel) 'V' blocks and spacers are usually used for work-piece location.

Is this (a): to prevent the work-piece from becoming permanently magnetized, or (b): to protect the magnetic chuck, or (c): some other reason?

Thanks,

M