- Joined

- Oct 14, 2014

- Messages

- 1,970

I scrapped out the Fanuc control on my Vectrax CNC mill and replaced it with Galil/Camsoft a couple years ago. I planned on CNCing the knee at that time but never got around to it. fast forward two years and I thought its about time. The pic shows the mill. there is a separate DRO for the knee visible in the pic that I have been using.

I had bought a magnetic encoder like this:

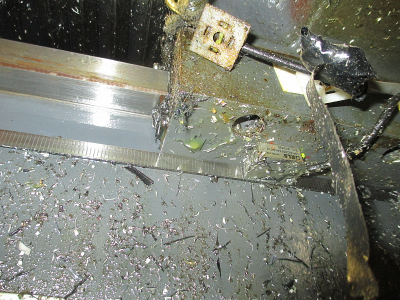

Got to work and machined a slot in a solid bar 20" long. Mounted this bar to the side of the knee with less than 10 thou run out in both X and Y end to end. Made a cover to fit over the top of the slot (removed in pic)

Fit the magnetic pickup to the end of a smaller rod to go the length of the slot and then extra to mount below the mill. made a shoe to hold the pickup just a couple thou above the tape. the top of the shoe also rides on the cover (removed in the pic) to hold it down close to the magnetic tape. The bottom of the small rod is mounted on a Heim ball joint and a slotted angle iron. trued everything up so the small rod never touches the slot in the big bar. paid a LOT of attention to detail here.

The whole idea of this design was to make it nearly impossible for metal chips to get near the scale and pickup head. With the cover on, the only opening is right at the bottom of the assembly.

I had bought a magnetic encoder like this:

MSR50H linear magnetic encoder (readhead),1/5/25/100 um,Good,like RENISHAW LM10 | eBay

Find many great new & used options and get the best deals for MSR50H linear magnetic encoder (readhead),1/5/25/100 um,Good,like RENISHAW LM10 at the best online prices at eBay! Free shipping for many products!

www.ebay.com

Got to work and machined a slot in a solid bar 20" long. Mounted this bar to the side of the knee with less than 10 thou run out in both X and Y end to end. Made a cover to fit over the top of the slot (removed in pic)

Fit the magnetic pickup to the end of a smaller rod to go the length of the slot and then extra to mount below the mill. made a shoe to hold the pickup just a couple thou above the tape. the top of the shoe also rides on the cover (removed in the pic) to hold it down close to the magnetic tape. The bottom of the small rod is mounted on a Heim ball joint and a slotted angle iron. trued everything up so the small rod never touches the slot in the big bar. paid a LOT of attention to detail here.

The whole idea of this design was to make it nearly impossible for metal chips to get near the scale and pickup head. With the cover on, the only opening is right at the bottom of the assembly.