-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Joined

- Jul 9, 2014

- Messages

- 613

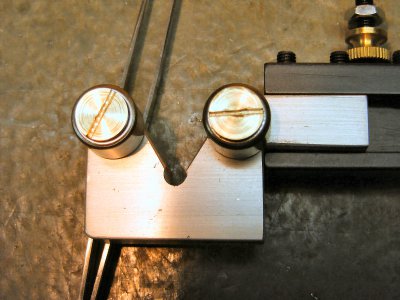

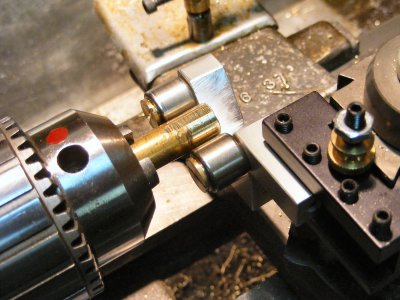

Here is how I do it with my lathe...Bob

Now that has stirred the old grey matter Bob.

I guess that it would not be too difficult to use a home made shallow aluminium vee block and one of the empty QCTP tool holders plus a G or F clamp to be able to raise and lower something held in such a clamping system .

Sort of make a mini temporary lathe mill for you not only get travel across and back and forth over the lathe bed you can get about 1.5 " vertical travel fairly easy by adjusting the tool holder height with the adjusting screws.

Thinking aloud.

I'm going to give that a go to see If I can get the flats I need , either on the QCTP or better still , I have a surplus mono block tool holder in machined steel similar to your tool holder.

- Joined

- Sep 23, 2010

- Messages

- 619

- Joined

- Jul 9, 2014

- Messages

- 613

It's 23.34 hrs Uk time I've been up since 05'10 hrs this morning , how the hell do you expect me to go to sleep with all that stuff twirling round in my head.

I've just had a thunk about using a bit of 1/2inch steel plate and putting in two high tensile 16 mm studs in it where the pinch bolts hold your frame anchoring it to the compound slot or the cross slide slot with one piece two studded plate suitably sized and precision fitted in the slots .

I can readily see that having a tower on each long stud made up of of precision flat washers or quality precision nuts to set diameters would allow me to move work up & down very easily . It may also lead to some " U " bolts being used to clamp round bar to a back plate that goes on the stud tower or drilled out square bar with holes and thread holes where needed.

I've just had a thunk about using a bit of 1/2inch steel plate and putting in two high tensile 16 mm studs in it where the pinch bolts hold your frame anchoring it to the compound slot or the cross slide slot with one piece two studded plate suitably sized and precision fitted in the slots .

I can readily see that having a tower on each long stud made up of of precision flat washers or quality precision nuts to set diameters would allow me to move work up & down very easily . It may also lead to some " U " bolts being used to clamp round bar to a back plate that goes on the stud tower or drilled out square bar with holes and thread holes where needed.

B

Bill Gruby

Forum Guest

Register Today

The Filing Rest is a very simple method. There is a kit for making one from Hemingway in the UK.

http://www.hemingwaykits.com/acatalog/Precision_Filing_Rest.html

"Billy G"

http://www.hemingwaykits.com/acatalog/Precision_Filing_Rest.html

"Billy G"

B

Bill Gruby

Forum Guest

Register Today

That one is cute David. I'll bet it works just fine.

"Billy G"

"Billy G"

- Joined

- Feb 1, 2015

- Messages

- 9,621

That's an interesting tool, Billy G,The Filing Rest is a very simple method. There is a kit for making one from Hemingway in the UK.

http://www.hemingwaykits.com/acatalog/Precision_Filing_Rest.html

"Billy G"

It looks like a great solution for those who don't have milling capability. I have always like hand filing. There is a certain satisfaction that comes from the intimate contact with your work that you can't achieve with power tools.

Bob

- Joined

- Mar 19, 2014

- Messages

- 2,681

Thanks for the link, I have not seen that file rest design before. If you do any kind of watch/clock repair with a like lathe. The file rest is a must have accessory for it...Dave.

A

Andre

Forum Guest

Register Today

When using a file to create a flat, I find it helps to rough it out then use a sharpie to mark the flat. Once marked, file just the center of the flat. Re-dye, then keep aiming for only filing the center of the flat. Should get it close for a set screw flat, and since it'll probably be in a pulley nobody will see it.