If I understand correctly, we are talking a live center that utilizes a chuck instead of a center. I can see the logic and the use of this.

Some key factors would be supporting all that weight and remaining true. A double set of bearing pressed onto the MT chuck then pressed into the chucks backing plate. A 3 jaw, unless it is adjustable, may through the piece out of alignment with the head stock so a 4 jaw would be of more value in my thinking. But you would have the ability to ensure that every part is properly aligned between head and tail stock.

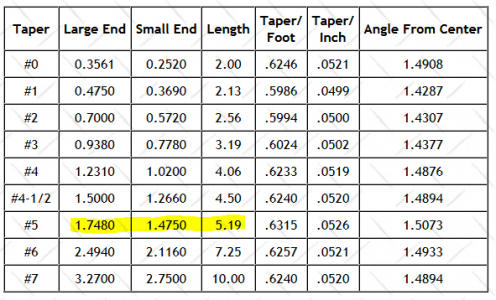

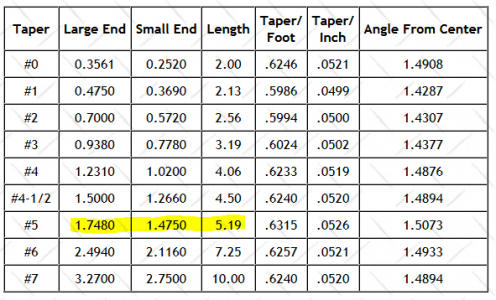

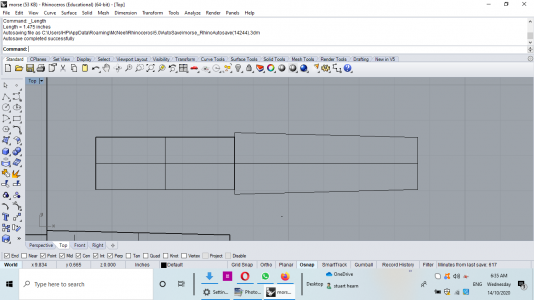

If I also understand this correctly, you question revolves around creating the correct taper to form the MT and ensure a proper fit into the tails stock. With a little math, you should be able to find the max and min diameters at a specific point along the MT shaft. Once you have the values, you could use a dial indicator to measure the stocks alignment or misalignment if you will by adjusting the tail stock to create the taper.

If you don't want to offset the tail stock and use the compound, place the dial indicator on the compound with the tool away from the part and measure the difference over the travel ensuring you are following using the correct distance. Again that can be monitored by another dial indicator.

You could run a test piece and using some blueing, check the fit in your tail stock before cutting the actual part.

I hope I understood your question correctly. If not, disregard.