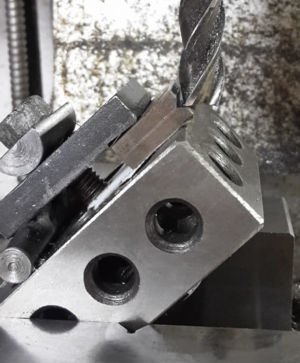

I have one of those 2 jaw chucks which caters for M5 upwards, but needed one for the smaller taps for a future project. Not wanting to spend money on a chuck which are notorious for having plenty of wobble, I decided to roll my own. I found an old hand drill chuck with a missing jaw which also relies on an inside taper to close the jaws.

I made a jaw carrier from a grade 5 bolt. This pushes the jaws against the internal taper to close them and, in use, transfers the torque necessary to turn the tap.

Next came the jaws, made from a truck spring. Lots of carefulling went into making these tiny parts. The mill setup got the V notch almost on centre. I had to squeak the difference using the surface grinder to get it spot on.

The jaws were drilled so I could rivet them to a mandrel, with the holes later serving to house a spring. The rivet held and the jaws were turned and tapered. Finally they were heat treated.

I think the chuck is satisfactory

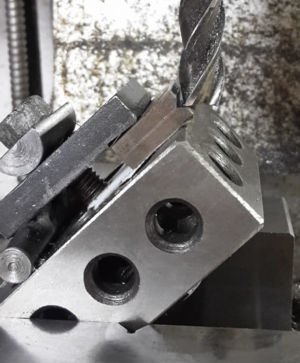

I made a jaw carrier from a grade 5 bolt. This pushes the jaws against the internal taper to close them and, in use, transfers the torque necessary to turn the tap.

Next came the jaws, made from a truck spring. Lots of carefulling went into making these tiny parts. The mill setup got the V notch almost on centre. I had to squeak the difference using the surface grinder to get it spot on.

The jaws were drilled so I could rivet them to a mandrel, with the holes later serving to house a spring. The rivet held and the jaws were turned and tapered. Finally they were heat treated.

I think the chuck is satisfactory