- Joined

- Jun 30, 2023

- Messages

- 19

I want to make pedal steel guitars and have discussed this with a member of the forum. He recommended getting a a Bridgeport J head milling machine. I bought a copy of A Guide to Renovating the Bridgeport "2J" Variable Speed Milling Machine, member suggested step pulley rather than a the vari drive, in his experience, "all the vari drives needed their vari drive rebuilt the step pulleys never did. " Was also suggested rotary table would be useful.

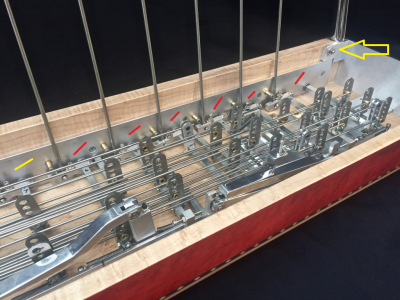

I'm wondering would one way to go for making parts for the guitar be to make punch and dies on the mill, then using some type of hydraulic, stamping, machine press or manual flypress? to make some of the parts, rather than trying to do those parts one at a time on the mill? ( see attached photos ) I can mill the end plates and key head on the mill out of an aluminium billet. Photos 1, 2 and 6.

If you do a Google image search on, pedal steel undercarriage, you will see various types of parts. You would get an idea of the types of parts I would be needing to make. Some parts like square bar and plate sections could be cut to size. I was advised to get a medium size cut off saw for this. Also have a look at the top of the guitar the metal neck section would need to be milled. I'm thinking of using aluminium, a certain grade, adonised, that lends itself to polishing. I would need a lathe I think to thread legs and other parts required. " 12 to 13 inch lathe with a 5c nose and single point threading capability , 5C is a collet and is a standard way to start (there many others). "

Lathe, 13" x 25", 13" x 30" 13" x 40" threading the ends of the ..... ( telescopic legs.... ) Which size would be suitable?

Any advice and help appreciated, thanks.

I'm wondering would one way to go for making parts for the guitar be to make punch and dies on the mill, then using some type of hydraulic, stamping, machine press or manual flypress? to make some of the parts, rather than trying to do those parts one at a time on the mill? ( see attached photos ) I can mill the end plates and key head on the mill out of an aluminium billet. Photos 1, 2 and 6.

If you do a Google image search on, pedal steel undercarriage, you will see various types of parts. You would get an idea of the types of parts I would be needing to make. Some parts like square bar and plate sections could be cut to size. I was advised to get a medium size cut off saw for this. Also have a look at the top of the guitar the metal neck section would need to be milled. I'm thinking of using aluminium, a certain grade, adonised, that lends itself to polishing. I would need a lathe I think to thread legs and other parts required. " 12 to 13 inch lathe with a 5c nose and single point threading capability , 5C is a collet and is a standard way to start (there many others). "

Lathe, 13" x 25", 13" x 30" 13" x 40" threading the ends of the ..... ( telescopic legs.... ) Which size would be suitable?

Any advice and help appreciated, thanks.