- Joined

- May 15, 2016

- Messages

- 98

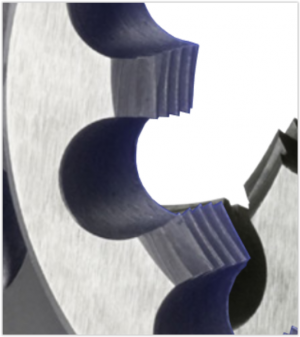

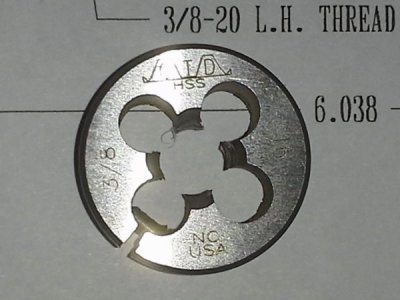

I am making a 1" O.D. 3/8-20 L.H. die. The only commercial dies I could find are made to order and cost $90. The basic die dimensions are found in Machinery's Handbook. The first 2-3 threads are to be tapered and form relieved behind the cutting edge to provide graduated cutting action until it reaches full depth. I am planing to cut the form relief on the lathe using a milling spindle mounted on the compound with tapered cutter similar to a 60 degree countersink. After heat treat I will sharpen using my Quorn and a mounted point in the 4 holes.

My question is: Is there a better way to provide the form relief than what I have planned?

My question is: Is there a better way to provide the form relief than what I have planned?