- Joined

- Mar 21, 2016

- Messages

- 251

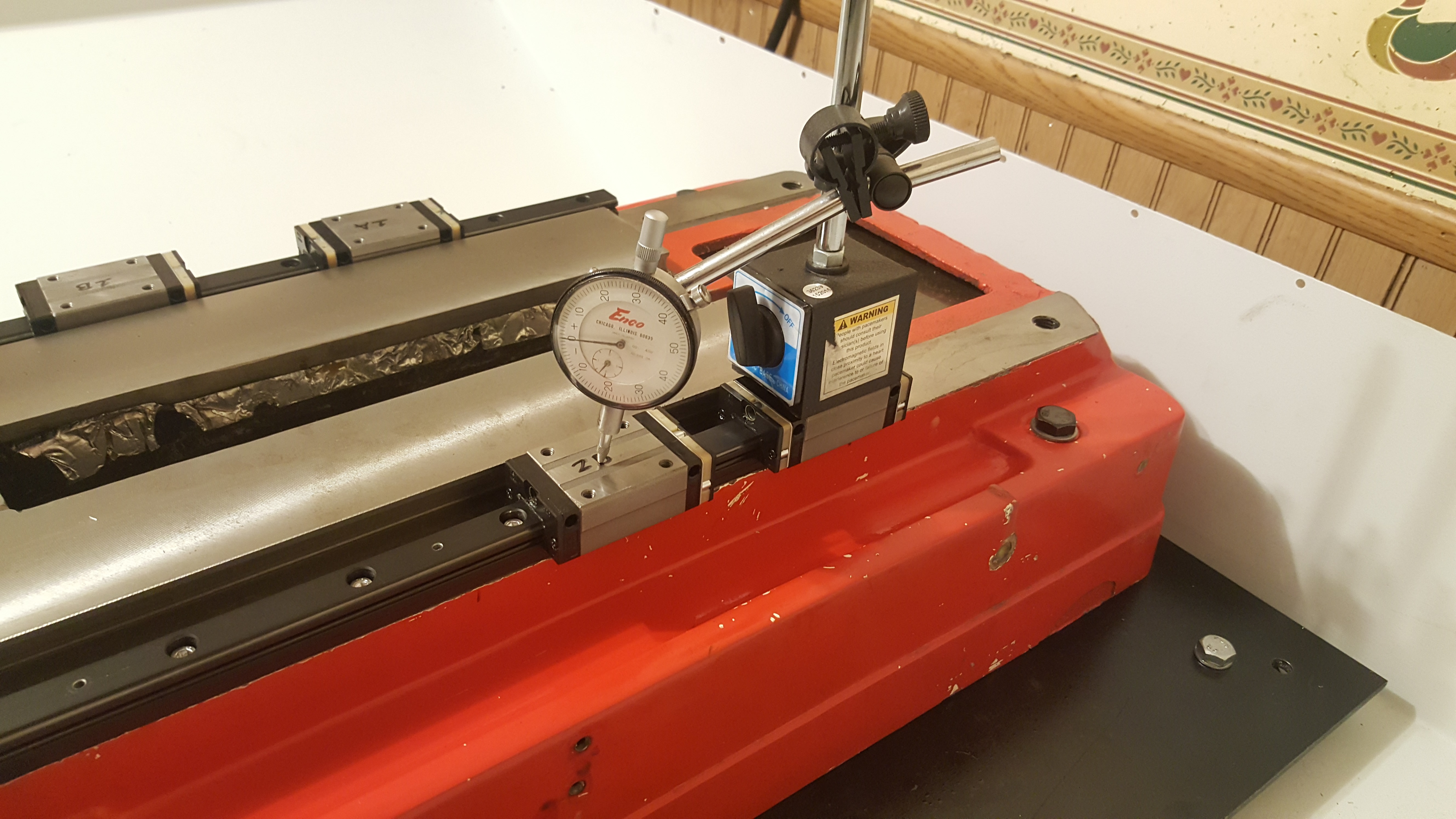

Ok, so a little background info. I'm in the process of converting my mill ( a PM45) over to linear rails, and i'm to the point where i'm getting ready to install the master rail for the y axis on the base. So I'm trying to measure the flatness of the master rail so i can then measure for parallelism on the slave rail.

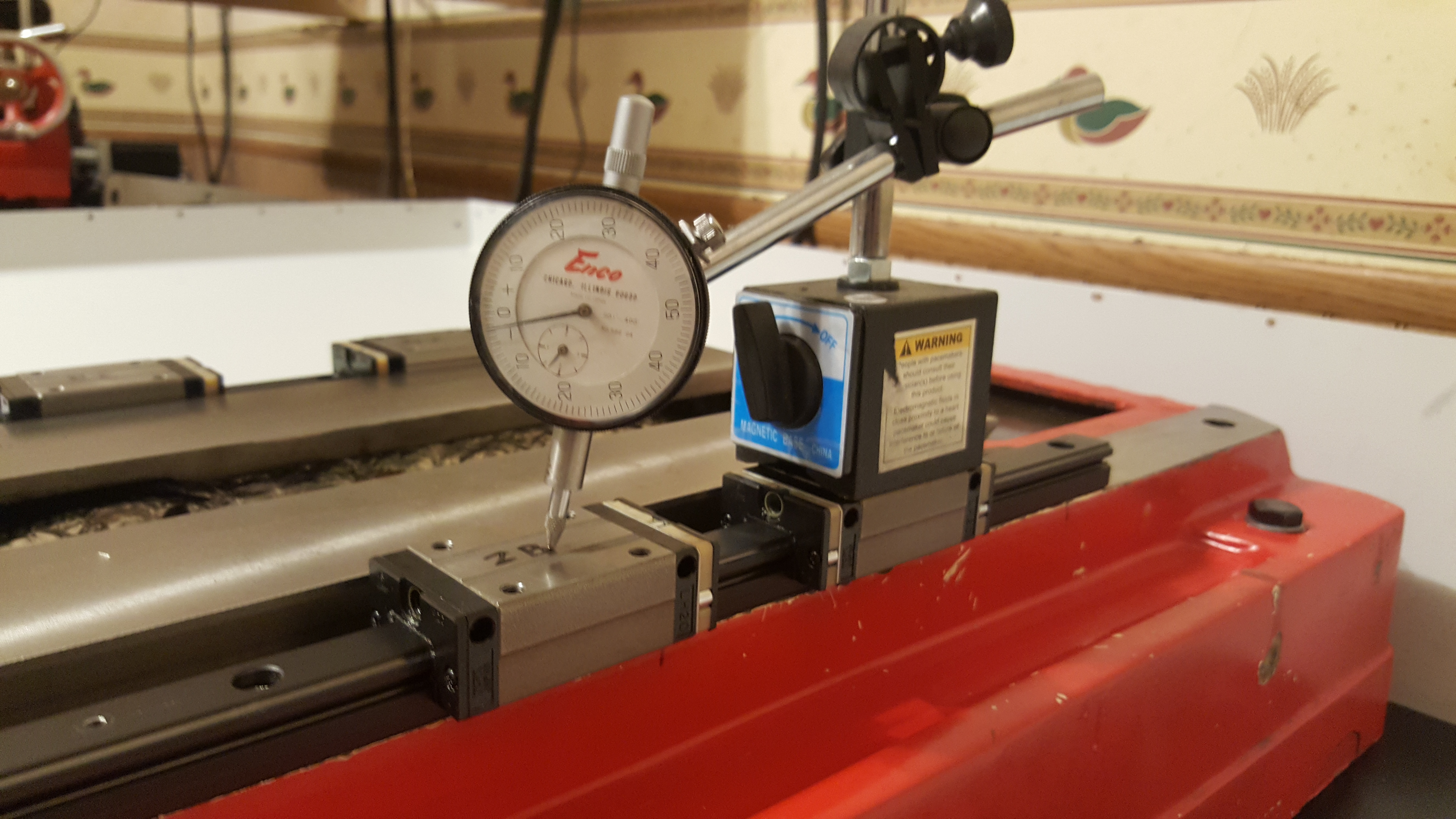

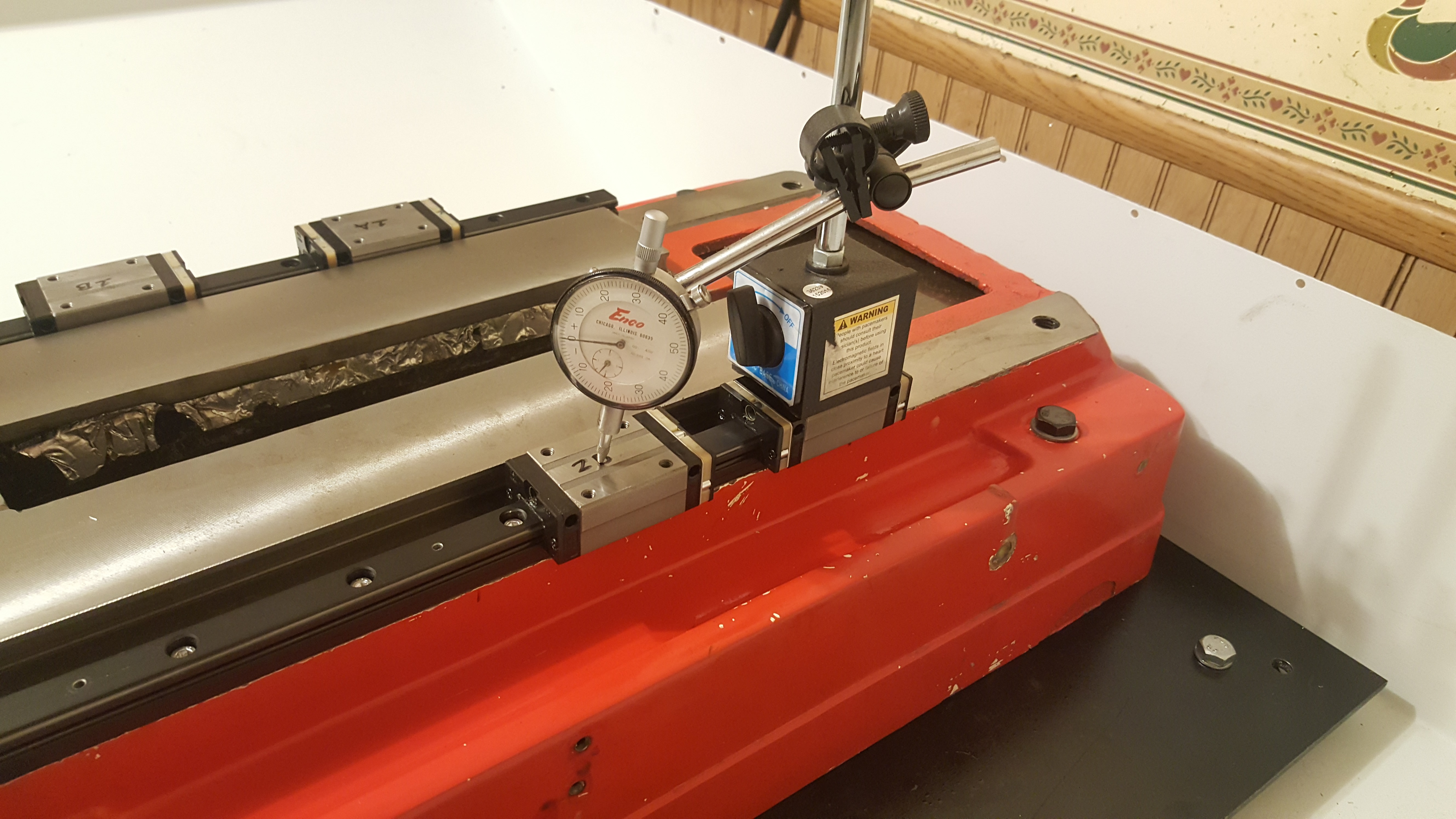

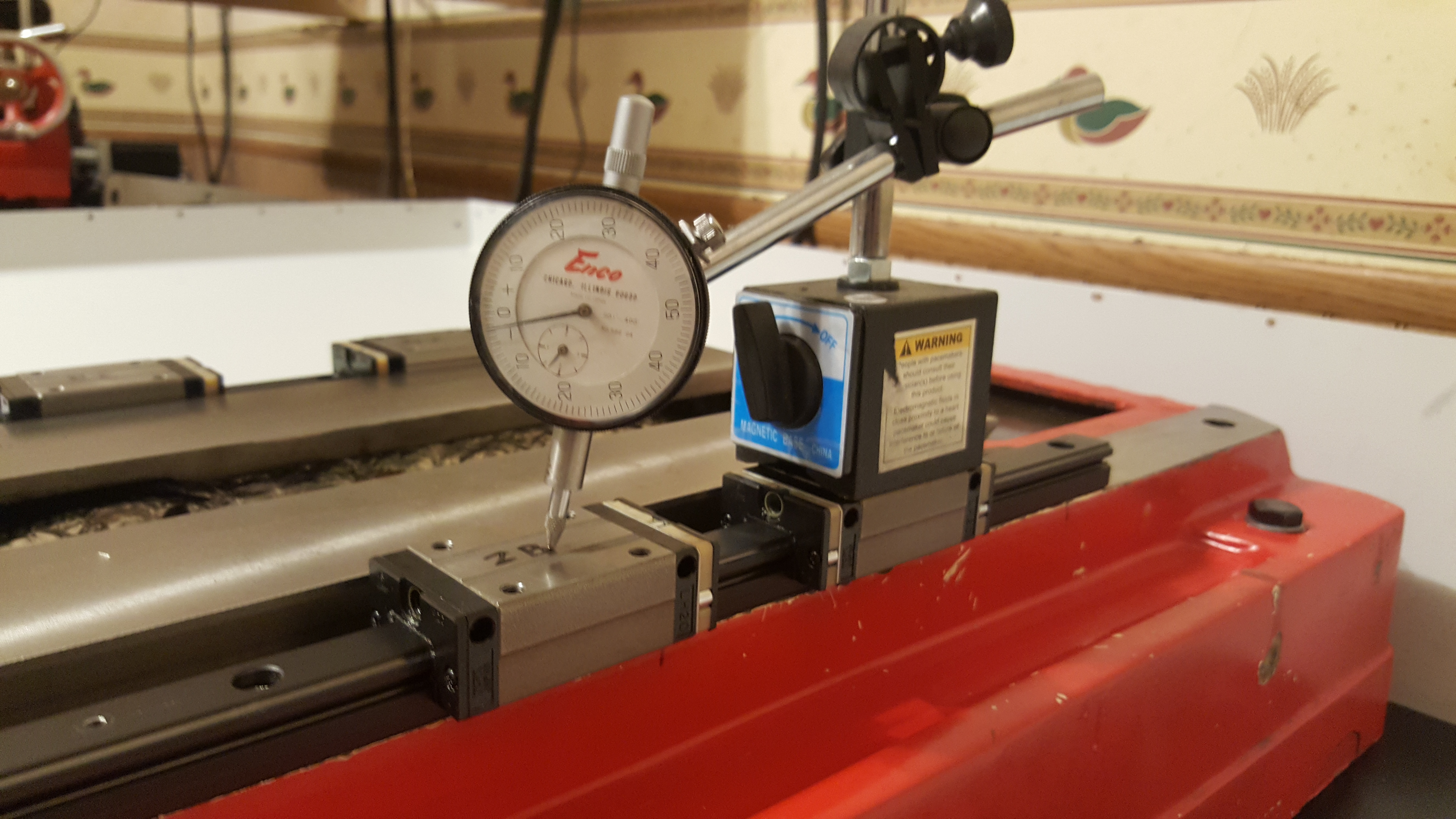

So on to the good stuff...I think i've come up with a good method for checking flatness, but would like to hear you guys opinions. In my efforts i think i've come up with a poor mans repeatometer.

so as i slide the blocks down the rail the indicator will measure deviation from the block with the indicator to the other block.

so if I'm thinking this correctly, i'm getting a fairly consistent deviation of -.002 to -.003 along the rail which tells me my rail is bowed down at a fairly consistent rate. So thoughts, is there a better way to do this? Am i completely off my rocker?

guess i should also add, that my surface plate isn't large enough to fit the base...and also the base is about 180lbs so moving it is a bit of a chore....

So on to the good stuff...I think i've come up with a good method for checking flatness, but would like to hear you guys opinions. In my efforts i think i've come up with a poor mans repeatometer.

so as i slide the blocks down the rail the indicator will measure deviation from the block with the indicator to the other block.

so if I'm thinking this correctly, i'm getting a fairly consistent deviation of -.002 to -.003 along the rail which tells me my rail is bowed down at a fairly consistent rate. So thoughts, is there a better way to do this? Am i completely off my rocker?

guess i should also add, that my surface plate isn't large enough to fit the base...and also the base is about 180lbs so moving it is a bit of a chore....