-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Measure threads

- Thread starter DavidR8

- Start date

- Joined

- Nov 27, 2012

- Messages

- 7,854

I got it from Amazon or ebay, I forget, no matter Amazon has it.

Nut & Bolt Thread Checker (Inch & Metric) - Tap And Die Sets - Amazon.com

Nut & Bolt Thread Checker (Inch & Metric) - Tap And Die Sets - Amazon.com

www.amazon.com

I got the metric & imperial combo, covers most common sizes. They also sell just metric & just imperial, those cover much more sizes.

- Joined

- Jul 8, 2018

- Messages

- 880

I'll second the Thread Checker. Identifying the thread pitch on a mystery bolt(/hole), verifying a newly-made thread ... mine gets a lot of use. Pricey to buy both the metric and imperial, but very much worth it.

- Joined

- Nov 23, 2014

- Messages

- 2,606

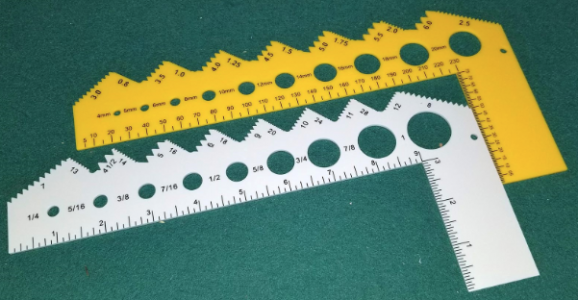

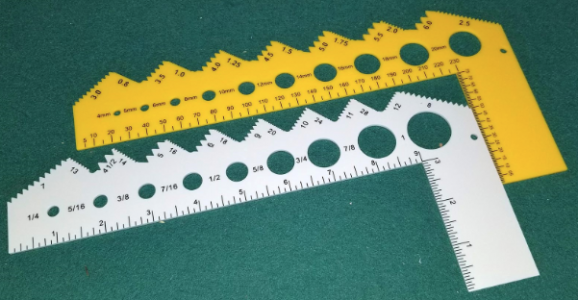

I use one of these, mine is actually a "Screw Chek'r" which is English threads only and around $20. The one pictured below is probably plastic for $4. I also have a set of plastic "gauges" that work really quickly. Just don't try to moose the screws/stud through the holes or it'll broach the plastic.

RJ has the best idea above, most manufacturers will go with off the shelf sizes of fasteners wherever they can. No sense reinventing the wheel (or bolt/screw) when you can buy them in bulk from someone else.

Bruce

RJ has the best idea above, most manufacturers will go with off the shelf sizes of fasteners wherever they can. No sense reinventing the wheel (or bolt/screw) when you can buy them in bulk from someone else.

Bruce

- Joined

- Feb 1, 2015

- Messages

- 9,605

The cheap and easy way is to assemble a set of nuts and bolts in the various sizes. In the current world though with both metric and inch threadas, it gets a little more complicated as some sizes will cross fit. I look to the equipment for a clue. Generally, inch and metric threads aren't mixed ( I know there were exceptions in the automotive industry a few decades ago). I look at other fasteners on the machine. If one is metric, they are most likely all metric and vice versa. Looking at a USA made lathe from the eighties and earlier, it would almost always be inch threads. Modern machines made overseas, regardless of whether the manufacturer is a US company or not will almost certainly be metric.