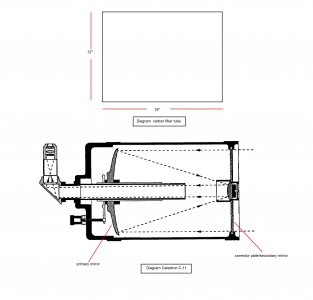

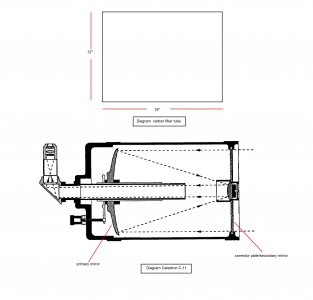

I'm in the process of rebuilding a telescope. The original aluminum tube was damaged in an accident and I have secured a replacement tube made of carbon fiber. The new tube is approx. 12" diameter and 16" long. Since optical elements are mounted on both ends of the tube, it is very important that the end cuts were performed accurately. I suspect that the factory did a good job, but just to be sure, I would like to check just how square the end cuts were made. Verifying the squaring and making adjustments now could save a lot of grief later.

Thanks, Frank

Thanks, Frank