- Joined

- Jul 20, 2012

- Messages

- 1,240

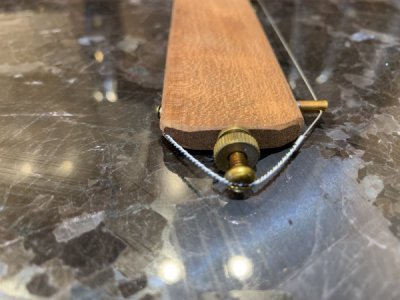

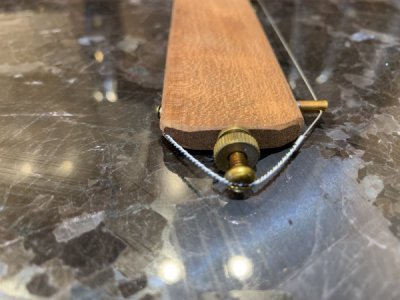

I ran across this cheese cutter and noticed it would make a nice little project. Making the body out of metal so it can go in the dishwasher.

Body metal choice would be interesting as far as how it would hold up to repeated dishwasher cycles. Aluminum probably would discolor but might look nice. Brass patina with heat cycles also interesting.

If anyone makes one post pictures.

Body metal choice would be interesting as far as how it would hold up to repeated dishwasher cycles. Aluminum probably would discolor but might look nice. Brass patina with heat cycles also interesting.

If anyone makes one post pictures.